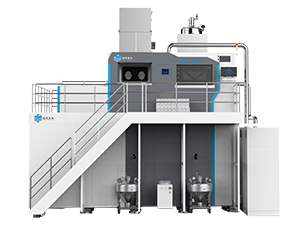

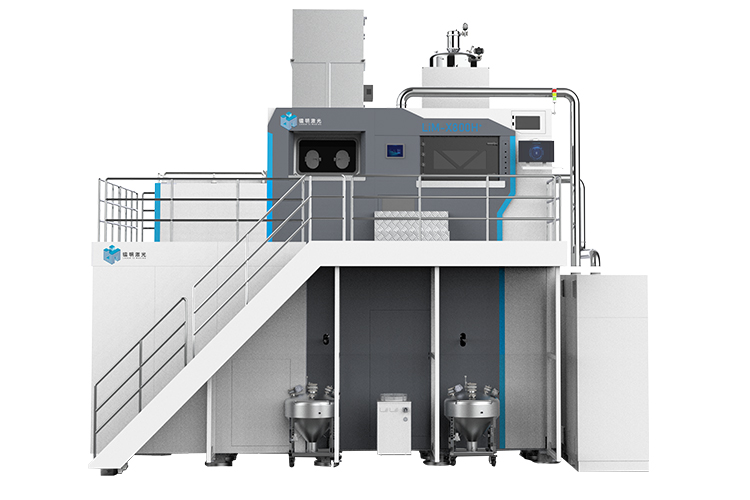

1.ULTRA HIGH FORMING SPACE。The net forming height reaches 2500mm, breaking through conventional sizes andexpanding printingspace.

2.HIGHACCURACY BUILDING PLATFORM。It adopts imported THK screw guide rail mechanism, and grating scale adjust-ment,which can realize positioning accuracy within 士0.005mm.

3.INTELLIGENT MONITORING。The system is equipped with powder bed monitoring module and a built-in camera. lt takespictures for powder bed after each powder spreading and fusing to monitor powder spread.ing quality and fusing quality for each layer based on the algorithm analysis and compari-son. Meanwhile, it can do powder replenishment automatically and alarm.

4.LONG LIFE FILTRATION SYSTEM。The dust collecting system has a blowback function and a long life time filterwith morethan 100,000 working hours to ensure uninterrpted printing.

5.SEPARATEDPOWDERRECYCLINGSYSTEM。Duringprinting, powder can be pumped with only one-click, and also it is equipped with alarge-capacity powder drop tank, a transfer tank, and an efficient sievingsystem. Thepowder is transferred with people isolated from powderthroughout the entire process innigh work efficiency and low failure rate.