In recent years, with the continuous increase in the demand for integrated forming of large and complex components in fields such as aerospace and energy equipment, traditional manufacturing methods have faced severe challenges in terms of efficiency, cost and structural freedom. TSC has been deeply engaged in the field of metal additive manufacturing for many years. Relying on its profound R&D experience and large-scale equipment manufacturing capabilities, it has officially launched the LiM-X2000H+, a super-laser and super-large laser selective melting equipment that has been verified by engineering, in response to the pain points of long printing cycles, difficult control of forming quality, and high requirements for equipment stability of large-sized components.

The synergy of 56 galvanometer mirrors has led to a significant increase in forming efficiency

The LiM-X2000H+ equipment has a forming size of 2000mm×2000mm×2700mm (W×D×H). With an ultra-large forming space as its core breakthrough, it meets the manufacturing requirements of the aerospace field for ultra-large-scale and highly complex components. The equipment adopts a matrix laser arrangement scheme, which can be equipped with up to 56 lasers. The doubling of the number of lasers drives a significant increase in forming efficiency.

Adopting an intelligent dynamic variable-speed powder spreading solution with multi-stage automatic speed change, it enables precise control in the printing area and rapid movement in the non-printing area, ensuring the quality and efficiency of powder spreading. Single-scraper bidirectional powder spreading structure simplifies the knife adjustment procedure, making it convenient and fast. The forming chamber is equipped with one set of scraper modules. Without disrupting the inert gas environment of the forming chamber, the scrapers can be replaced online, solving the problem of scraper wear during long-term printing. The scraper drive guide rail adopts a double-layer sealed protection design, which increases its service life by more than five times.

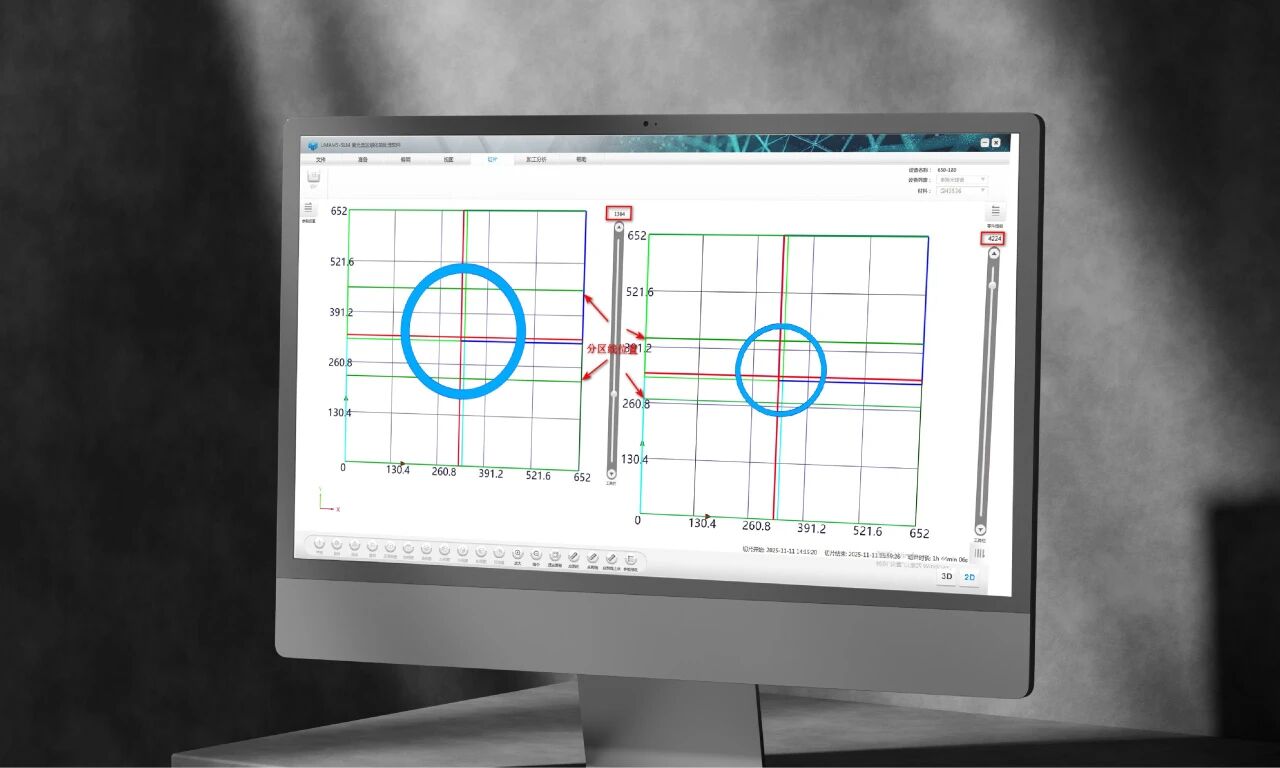

It can achieve multi-laser dynamic zone optimization. The system analyzes the shape and area of each layer of printing in real time, automatically calculates and optimizes the scanning zone boundaries of each laser, reduces waiting and idle time, releases the parallel processing potential of multiple lasers, and takes into account both printing quality and printing efficiency.

Illustration of the multi-laser zone interface

Optical redundancy design, intelligent fault tolerance

The LiM-X2000H+ optical path is reliable. The 56 laser spot size and energy density of the equipment are consistent. The laser power deviation is ≤±5W, and the spot size deviation does not exceed 5%. The mechanical properties and roughness of each area of the equipment are highly consistent, and the forming quality of the parts is high.

Adopting a self-developed intelligent fault-tolerant system and relying on advanced algorithms to achieve laser redundancy guarantee, it has the ability to automatically diagnose, isolate and dynamically optimize the scheduling of single-point faults. Under normal operating conditions, the 55 laser prints in coordination. However, when an unexpected failure occurs in one of the laser systems within the printing range, the backup optical system automatically starts, and the two adjacent optical systems in the corresponding longitudinal single column can automatically cover the printing area and continue to work, ensuring that the printing is not interrupted and significantly enhancing the reliability and consistency of continuous printing of large components.

This solution provides a strong guarantee for the continuous forming of large workpieces and effectively avoids forming defects and economic losses caused by optical system problems.

Multiple configuration upgrades ensure high-quality and efficient forming

The LiM-X2000H+ equipment has improved the structural design of the wind field, making the airflow in the forming chamber more uniform and stable. Even under the super-large span, smoke and dust can be effectively removed, making the printed surface bright and clean. It enhances the uniformity and stability of multi-laser printing in super-large format, effectively ensuring the one-time forming of printed parts.

The LiM-X2000H+ is driven by a servo motor, combined with precision ball screws, guide rails and high-precision grating rulers, to achieve closed-loop control and ultra-heavy-load dual drive. The Z-axis positioning accuracy is better than 10μm, and the repeat positioning accuracy is better than 5μm, ensuring the consistency of film thickness and forming stability during large-sized and long-cycle printing processes.

Dual quality control, full traceability throughout the process

The equipment integrates a dual quality monitoring system, which collects key parameters such as scraper torque, position, forming chamber pressure, oxygen content, temperature, dust removal air volume, and filter element pressure difference in real time, and records them completely in the log system. This enables full traceability of the printing process and provides data support for process optimization and quality analysis.

The LiM-X2000H+ is equipped with a powder bed monitoring system. The high-definition camera can capture and store real-time images of each layer of powder spreading and scanning. Combined with image processing algorithms, it intelligently assesses the quality of powder spreading. If powder spreading defects are detected, the system automatically controls the powder spreading mechanism to re-spread the powder, ensuring that each layer of powder is evenly spread without any flaws, thus guaranteeing the forming quality of the parts from the source.

Supports intelligent galvanometer calibration without manual intervention, with a single light galvanometer calibration accuracy of ≤±0.05mm. The multi-light overlap accuracy error is ≤±0.1mm, significantly improving the consistency of print quality and shortening the preparation time.

Safety redundancy design ensures production safety

The LiM-X2000H+ has passed CE safety certification, ATEX explosion-proof directive, FDA laser safety certification and SIL Level 3 relay safety certification. It is equipped with multiple monitoring interlock devices, pressure monitoring, temperature monitoring and other multiple guarantee systems to ensure the safe and stable operation of the equipment in high-load environments.

Equipped with a long-lasting filtration system and featuring reverse blowing function, the filtration grade is H13. It is equipped with a cyclone dust removal module, which can collect large particles in the smoke dust, reduce powder waste, lower costs, and effectively extend the service life of the filter element. The service life of the filter element exceeds 100,000 hours, and there is no need to replace the filter element throughout the entire service life cycle of the equipment, ensuring continuous printing of the equipment. The ash bucket of the filter adopts a top-lifting structure. The circulating purification system is equipped with monitoring of oxygen content, temperature and pressure to ensure safe use.

The release of LiM-X2000H+ marks another step forward for TSC in the field of super-large metal additive manufacturing equipment. Over the past ten years, we have made steady progress and continuously advanced the research and development as well as application expansion of high-end equipment with our sustained technological accumulation. In the future, TSC will continue to focus on the research and development and promotion of high-performance, high-reliability and intelligent equipment, providing more efficient and stable additive manufacturing solutions for fields such as aerospace, energy and power, and high-end molds.