Ten years of craftsmanship have forged exquisite workmanship. TSC has always been committed to promoting the leap of metal 3D printing technology from "printable" to "applicable". In this leap, post-processing is a crucial link that determines the transformation of components from "raw materials" to "high-quality products".

SLM (Selective Laser Melting) technology, with its high precision, high efficiency and highly customizable capabilities, is transforming the way parts are manufactured, injecting strong impetus into the intelligent manufacturing upgrade of fields such as aerospace, energy and power, automotive manufacturing, and 3C electronics.

The metal 3D printing process involves multiple steps. Only by striving for excellence in each step can a "masterpiece" that meets the needs of users be obtained. Directly printed and formed parts are not the final delivered state of the product. They are usually still in a "blank" state and have problems such as uneven energy distribution, high surface roughness, and residual stress. Therefore, before the product is delivered, there is still a long and rigorous post-processing period.

Post-processing: The "Fine processing" that cannot be ignored

Post-processing is not merely a simple process of "mending and patching", but rather a systematic and refined remanufacturing process. It runs through the entire life cycle of the parts and mainly includes three core links:

Support structure removal: Precise separation, laying the foundation

Support structure removal is the first step in post-processing. Common methods include wire cutting and manual tool removal. Wire cutting uses the high temperature generated by discharge to separate the support structure from the parts, offering higher precision but relatively higher costs. It is suitable for components with strict requirements for dimensional accuracy. Manual tool removal is more flexible but less efficient, and it requires higher experience and technical skills from the operator. It is suitable for workpieces with simple structures.

Heat Treatment: The "Resetter" of Intrinsic Properties

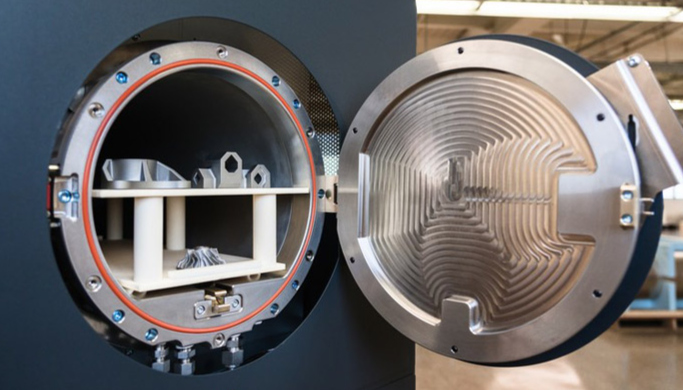

Heat treatment is an effective step to improve the internal structure and properties of parts. Through processes such as stress relief annealing, hot isostatic pressing, aging treatment, and solution treatment, we effectively release internal stress, close internal pores, and optimize material structure, significantly enhancing the strength, toughness, and fatigue life of parts.

#Stress relief annealing improves the dimensional stability of parts by heating them to release the residual stress inside.

#Hot isostatic pressing, under high-temperature and high-pressure conditions, fills the internal pores of parts, further enhancing the density and performance of the parts.

#Aging treatment causes the microstructure of parts to change within a certain period of time, thereby achieving the purpose of increasing hardness and strength.

#Solution treatment involves heating the alloy to a high-temperature single-phase region and maintaining it at a constant temperature to allow the excess phase to fully dissolve into the solid solution. Then, it is rapidly cooled to obtain a supersaturated solid solution, thereby enhancing the comprehensive performance of the parts.

Surface treatment: "Double Enhancement" of appearance level and performance

Surface quality is directly related to the user experience and lifespan of parts. TSC offers a variety of treatment methods, including mechanical polishing (such as sandblasting, vibration polishing, and magnetic polishing), chemical polishing, electrolytic polishing, and CNC precision machining, to meet the strict requirements of different industries for surface finish, precision, and corrosion resistance.

#Sandblasting uses the impact effect of high-speed sand flow to clean and roughen the surface of parts, making it more uniform.

#Vibration polishing removes minor surface defects by causing the parts to rub against the polishing medium through vibration.

#Vibration polishing removes minor surface defects by causing the parts to rub against the polishing medium through vibration.

#Chemical polishing achieves a smooth and flat surface of parts through chemical reactions.

#Electrolytic polishing utilizes electrochemical principles to microscopically dissolve the surface of parts, thereby enhancing the surface finish.

#CNC precision machining performs high-precision cutting on parts to ensure their dimensional accuracy and surface quality.

Industry Application: Ensuring Parts Are "in the Right Place

Different industries have their own emphases on the performance, appearance and precision of parts. Only by formulating appropriate post-processing solutions based on the actual needs of users can the performance and value of components be fully released, enabling them to play a key role in practical applications. With its profound technological accumulation, TSC has a deep understanding of the demands of various industries and provides precise and suitable post-processing solutions for different application scenarios.

The aerospace field has strict requirements for the fatigue strength and density of parts. Hot isostatic pressing is often adopted to effectively eliminate internal micro-defects, enhance the strength and toughness of materials, and thereby increase the reliability of components under complex working conditions. At the same time, precision grinding is combined to ensure the accuracy of the profile and surface quality, guaranteeing that every component meets the performance requirements of aerospace products.

3C electronic products are directly targeted at consumers. They should not only be aesthetically pleasing but also durable and wear-resistant. Mechanical polishing is often used to make the product surface smooth and fluid, enhancing the visual effect. Then, through the anodizing process, a hard oxide film is constructed on the surface of the components, which not only enhances corrosion resistance and wear resistance, but also enriches the color through dyeing and other processes, meeting the market's dual pursuit of aesthetics and functionality.

Medical implants need to come into direct contact with human tissues, and thus have extremely high requirements for post-treatment. Usually, manual polishing is carried out first. Relying on the operator's experience and skills, the surface of the implant is initially finely ground to remove obvious flaws. Electrolytic polishing is then carried out to further reduce the surface roughness, making the implant smoother, reducing irritation to human tissues, and improving biocompatibility.

Ten years of meticulous craftsmanship, building dreams with dedication. TSC has always been dedicated to the in-depth research and development and industrial application of metal 3D printing technology, forming a complete industrial closed loop from equipment R&D and manufacturing, process development, printing services, to mechanical processing, quality inspection and delivery, and building a strong hidden competitiveness. Standing at the starting point of the new decade, we will continue to break through technological boundaries and expand application frontiers, truly transforming metal 3D printing from a cutting-edge technology into a core driving force for the intelligent upgrade and high-quality development of the manufacturing industry.