In the complete chain of metal 3D printing, from the digital model to the final part, it needs to go through steps such as model optimization, preprocessing, product printing, post-processing, quality inspection, and product delivery. Among them, "print model optimization" and "preprocessing", as the key links before on-machine printing, affect the subsequent printing quality and efficiency.

Based on its rich experience in providing customized product services for metal 3D printing and in the collaborative development of equipment software and hardware, TSC precisely controls the pre-processing stage before printing.

Design optimization: Lightweight and high-quality

In the "print model optimization" stage, structural design is of Paramount importance. TSC breaks through the thinking barriers of traditional design, employs various design methods such as topology optimization, and starts from additive thinking to achieve structural optimization of components, completing the leap from "meeting demands" to "performance-driven".

Topological optimization is a method for determining the best design scheme. Under given constraints, loads and boundaries, it uses algorithms to add and remove materials in the specified design space to achieve performance goals. Combining topology optimization with additive manufacturing helps products achieve lightweight, high performance and high reliability.

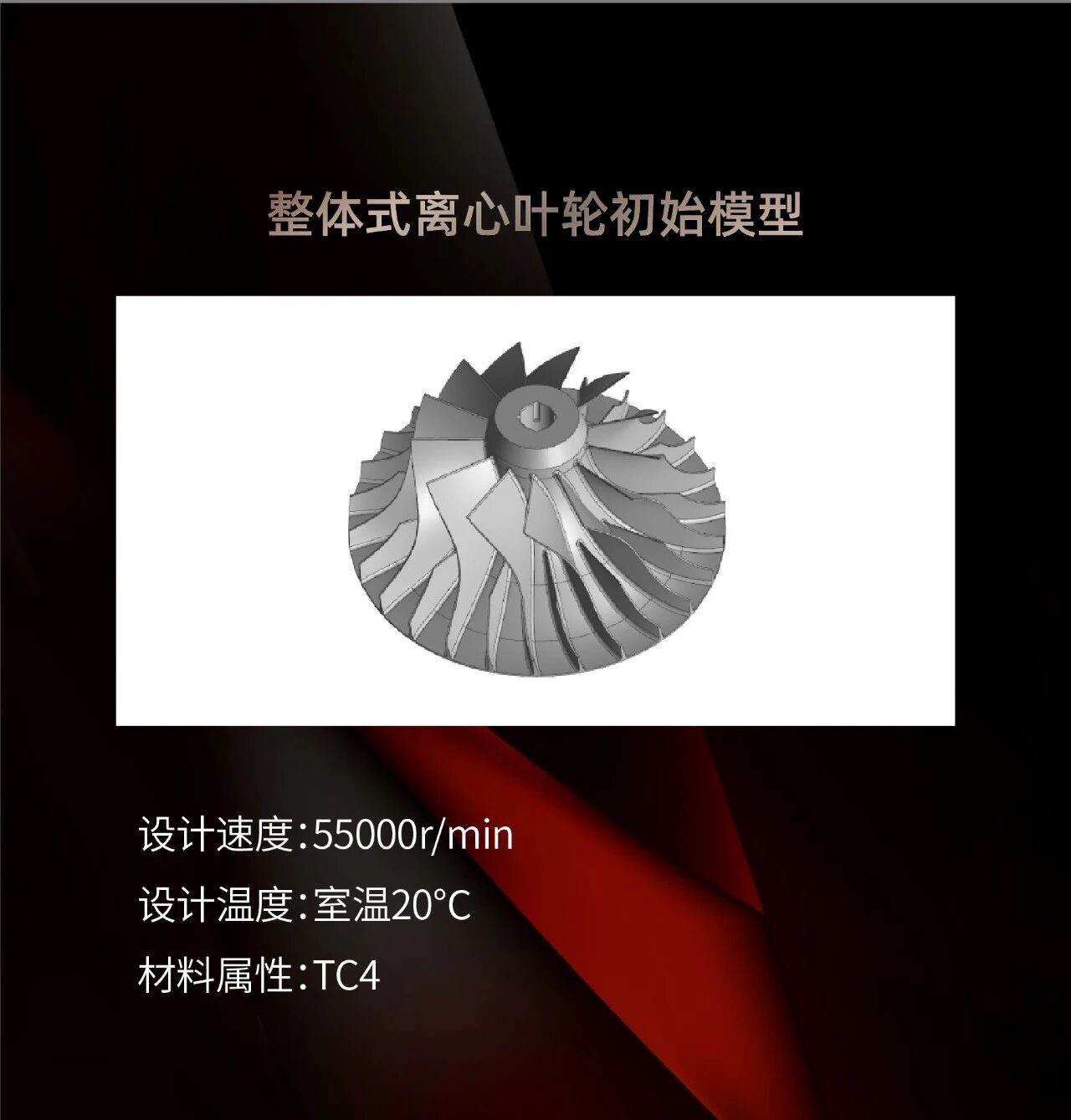

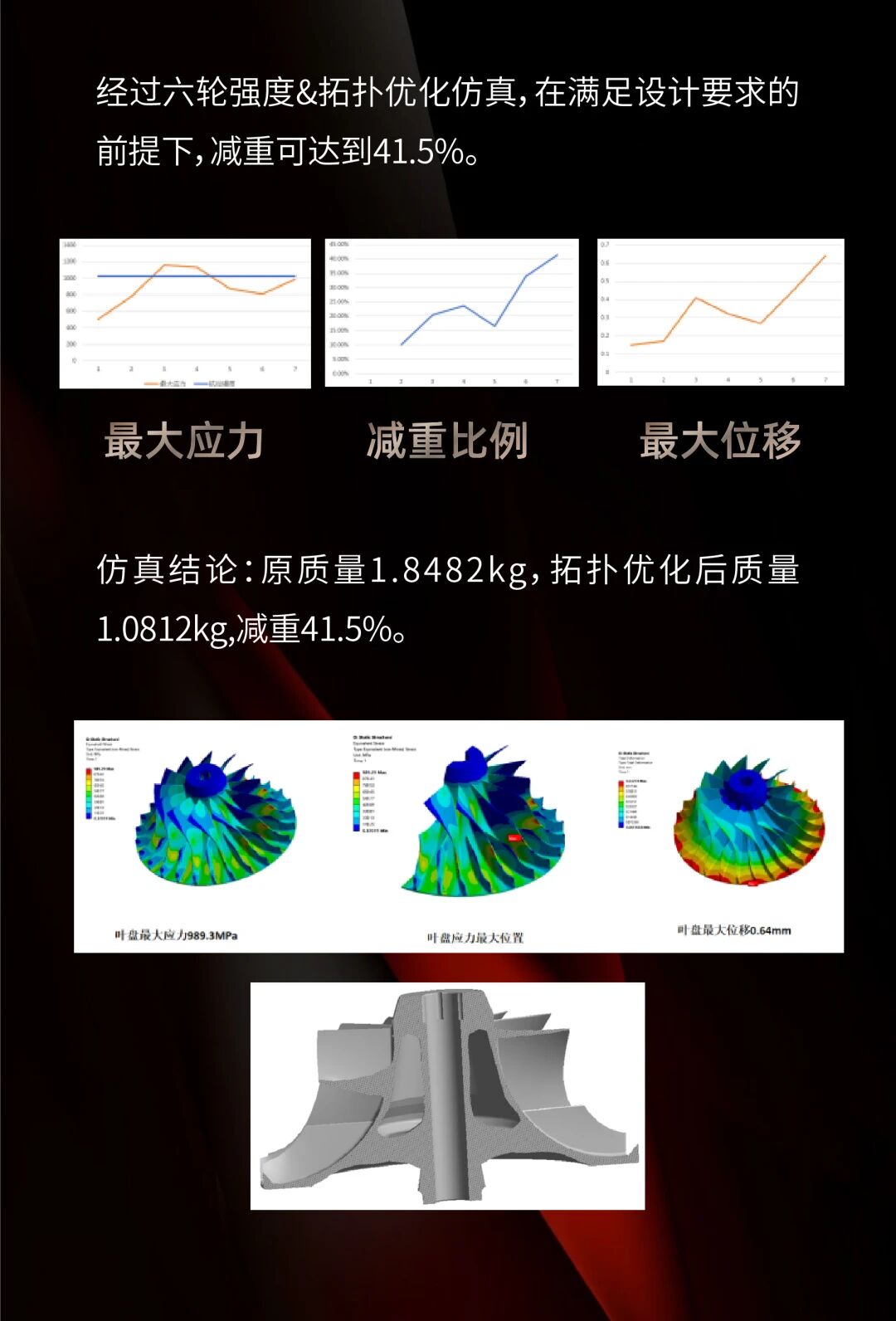

Taking the integral centrifugal impeller commonly seen in the energy and power field as an example, without changing the blades and aerodynamic shape of the centrifugal impeller, by optimizing the design of the backplate contour, core contour and internal structure of the centrifugal impeller, the weight of the centrifugal impeller can be reduced to the greatest extent while meeting the requirements of strength and deformation.

After six rounds of strength and topology optimization simulations, the weight was reduced by 41.5% while meeting the design requirements, achieving a unified goal of being lightweight and high-strength.

Upgraded from a "weight loss tool" to a "performance customization platform", TSC, by leveraging topology optimization and lattice structure solutions, can provide customers with customized and integrated additive manufacturing solutions covering "design - simulation - manufacturing". Based on performance requirements, it can determine the best material layout, break through the barriers of traditional shape optimization, greatly expand the design space, and fully leverage the potential of additive manufacturing. Achieve the harmonious unity of performance and weight of complex-structured components.

Intelligent software: Self-developed LiMAMS-SLM

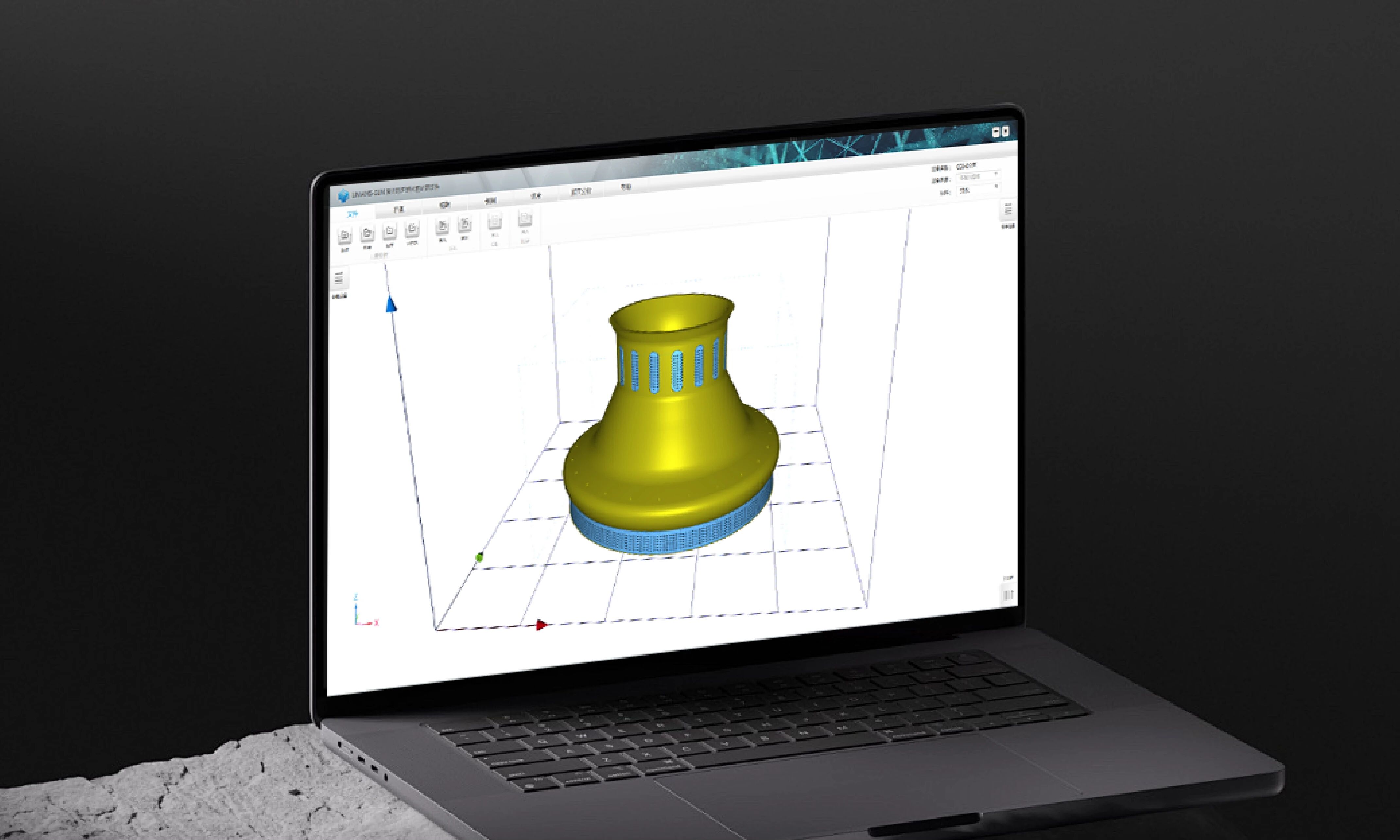

The LiMAMS-SLM preprocessing software independently developed by TSC has been updated and iterated to version 3.0, covering the LiM-X series SLM device matrix. In addition to the conventional functions such as digital model creation, 3D STL part import, 2D CLI contour data import, and part movement/rotation/slicing/path planning, it has undergone comprehensive innovation from user experience to core algorithms.

Full format compatibility, seamless data connection

The software supports industry-standard STL files, two-dimensional CLI format contour data and self-developed TLSF slice data. It can be exported as TLSF, STL, and LMJOB format files, ensuring smooth flow from digital modeling to printing tasks and providing convenience for subsequent review and process iteration.

The human-computer interaction is friendly, and the operation is simple and efficient

The software adopts a newly designed UI interface, featuring a simple style and reasonable layout. It supports free dragging and hiding of parameter lists and part lists, allowing users to flexibly customize their workspace based on the current task focus. Combined with basic operations such as rotating, zooming, and copying arrays, it brings an intuitive and focused operation experience.

UI interface illustration

Three-dimensional projection, precise and efficient layout

By introducing the 3D projection function, the projection of parts on the substrate is visualized. Users can perform position calibration and layout planning intuitively and accurately when placing parts. Precise positioning and space optimization are achieved in the first step of printing preparation, effectively improving the substrate utilization rate and batch printing efficiency.

Three-dimensional projection interface illustration

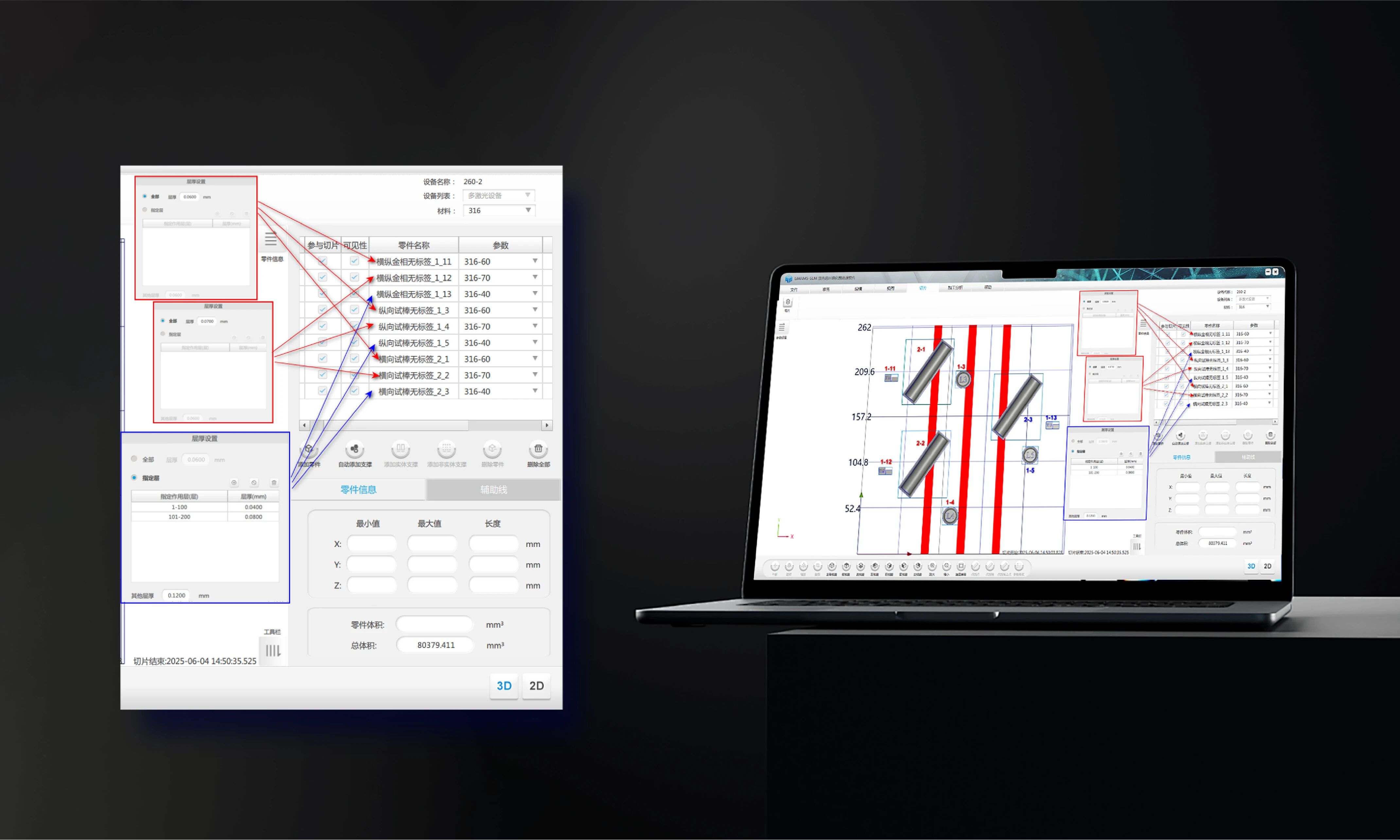

Variable layer thickness, intelligent slicing

It has broken through the limitations of traditional slicing technology, achieving the "multi-dimensional variable layer thickness" slicing function, and supports setting different printing layer thicknesses for different parts in the same printing task. Different layer thickness strategies can also be applied to different height areas of a single part. By integrating core parameters such as laser power and scanning speed required for different printing layer thicknesses, users can seamlessly integrate high-precision printing areas and fast printing areas on a single component, truly achieving intelligent manufacturing that is "fast where it should be and precise where it should be".

Illustration of the variable layer thickness interface

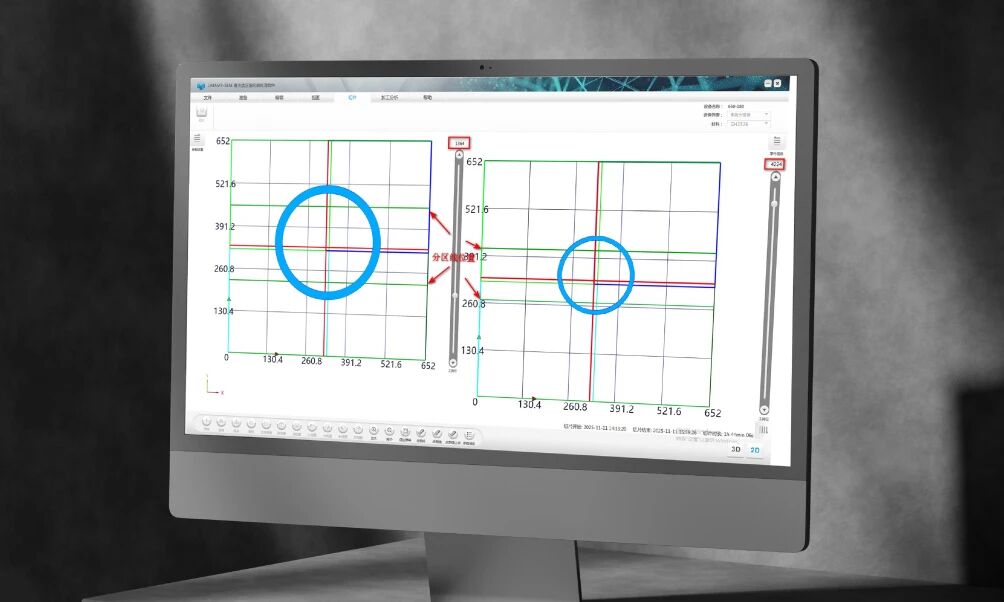

Multi-laser dynamic partitioning, unleashing printing efficiency

For large-sized, multi-laser metal 3D printing equipment, LiMAMS-SLM software is equipped with an intelligent dynamic partitioning algorithm. The system analyzes the geometric shape and area of each layer of the component in real time. Relying on advanced algorithms, it automatically optimizes the scanning partitioning boundaries of each laser head, reduces idle travel and waiting time, and maximizes the parallel processing potential of multi-laser equipment. Improve the overall printing efficiency.

Illustration of the multi-laser zone interface

Path preview and flexible parameter management

LiMAMS-SLM's flexible layer-by-layer and line-by-line scanning preview function enables precise analysis of parts before processing. Users can view the scanning path and jump path, and flexibly choose various scanning strategies such as checkerboard, bar, upper and lower surface partitioning, and contour. Support parameter package encryption processing to enhance the management of core process parameters; At the same time, some parameters are opened for users to fine-tune.

Support in-depth customization for various industries

According to the usage scenarios of users in different industries, we can conduct in-depth customization, develop personalized functions, and tailor suitable pretreatment solutions.

As a pioneer in the field of metal 3D printing, TSC has an integrated control capability covering design optimization, intelligent pre-treatment, stable printing, precise post-processing and strict quality inspection.

Ten years of hard work, creating the future with intelligence. Xinjinghe will continue to achieve the transformation from "quasi-printing" to "high-quality forming" through full-process solutions, promoting metal 3D printing technology to a new stage that is more efficient, more accurate and more intelligent.