In recent years, metal 3D printing technology has been continuously developing and improving, with application scenarios covering large-scale manufacturing fields such as aerospace as well as civilian markets like consumer electronics and intelligent robots. The demand for printing fine components in various industries is constantly rising, and the requirements for product precision, surface finish and consistency are becoming more stringent. Based on the stable and efficient production of equipment, TSC has launched a fine structure printing solution through multiple process optimizations, significantly raising the quality limit of metal 3D printing for processing small-sized complex components. It provides users with an additive manufacturing solution that combines advanced technology and engineering practicality.

Components in industries such as consumer electronics, intelligent robots, and low-altitude flight are characterized by small size, fine structure, and high quality requirements. They often contain lattice, porous, and lattice structures, or have complex internal flow channels. Manufactured by traditional techniques, it is difficult to process and it is hard to improve the surface quality by means such as grinding.

Based on its self-developed LiM-X series SLM equipment, TSC has proposed a fine structure printing solution, which can directly form complex and precise components. The surface roughness of the printed products is ≤Ra 3.2μm, and the printing accuracy is within ±0.05mm. The details are clear, the structure is complete, and the surface quality is excellent. It not only avoids the dimensional errors caused by post-processing, It has greatly shortened the manufacturing cycle.

Superalloys possess high high-temperature strength, excellent oxidation resistance, corrosion resistance and fatigue performance, and have good microstructure stability and service reliability at various temperatures. Therefore, it is often used in fields such as aerospace engines, energy, and chemical engineering.

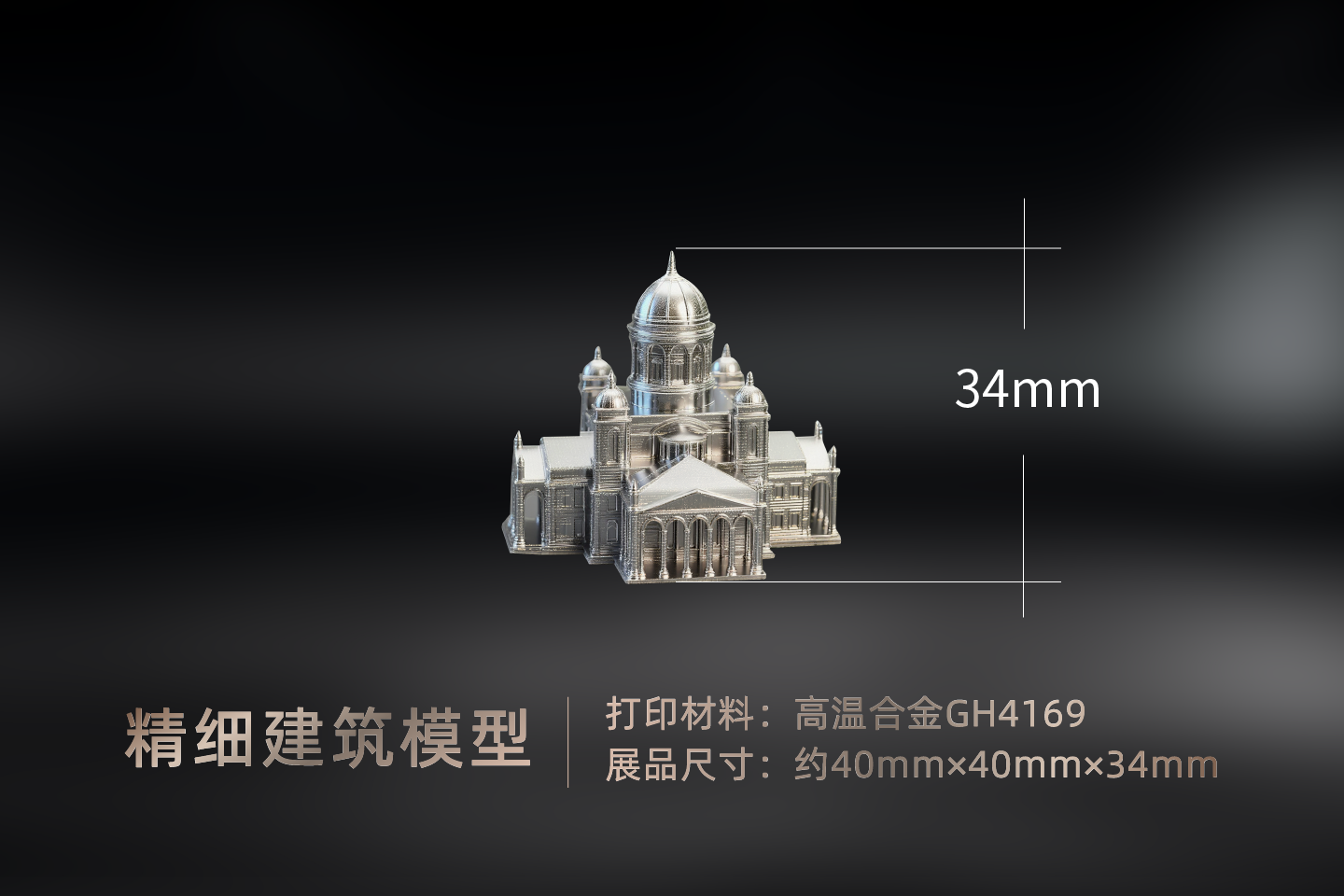

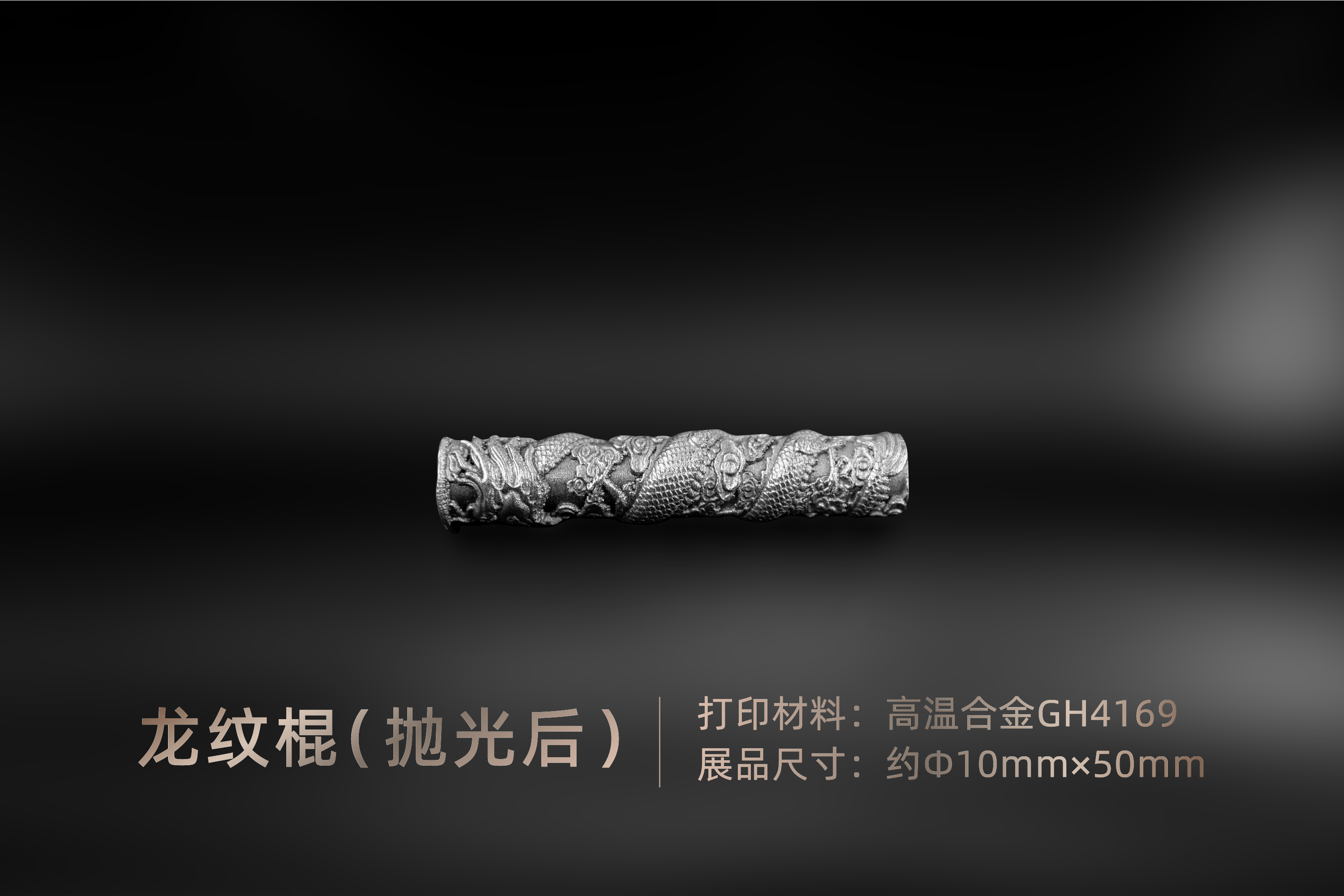

TSC, with the help of the LiM-X150A equipment and the fine structure printing process solution, prepares process exhibits with high surface finish and fine structure.

This model features clear detailed textures, complete fine structures, distinct layers of Roman Columns, clearly visible window lattice structures, and a pole diameter of only 0.2mm at the eaves.

In addition, there were also printed craft exhibits such as dragon-patterned sticks and Terracotta Army ornaments. The dragon-patterned stick is engraved with lifelike dragon-shaped carvings, with the scales clearly visible. The cloud-patterned decoration is exquisite and elegant, and the overall details are rich and compact. The details of the Terracotta Army figurines are intricate yet clearly visible. Their expressions are depicted in every detail, and the armor details are vividly presented. The overall look is lively and imposing.

The surface roughness of the superalloy specimens formed by this scheme was tested to be only Ra 2.3μm.

Pure copper and copper alloys have excellent thermal and electrical conductivity as well as corrosion resistance, and are widely used in industries such as aerospace, mechanical manufacturing, shipping, automobiles, and 3C electronics. For example: heat exchangers, coolers, water-cooled molds, electronic components, engine parts, pipe fittings, etc.

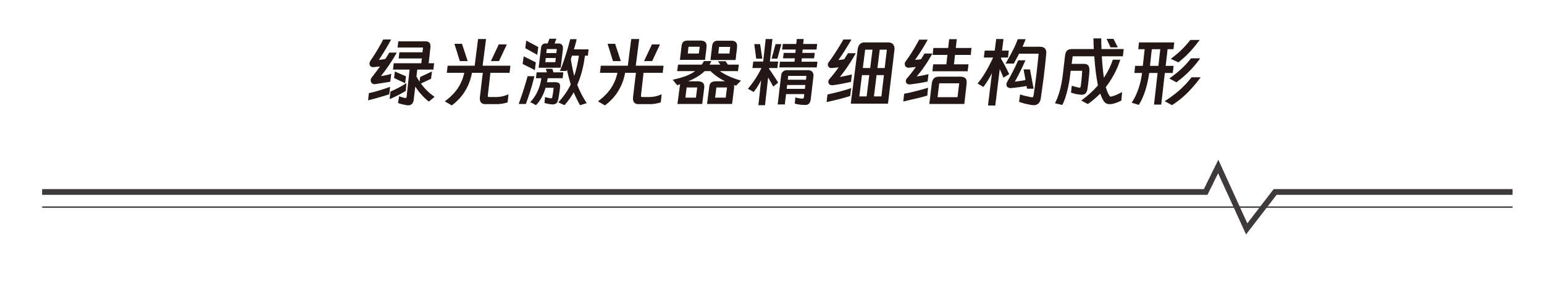

TSC uses the LiM-X260E green laser equipment to print pure copper embossed badges. The badge adopts a square multi-hole structure design, with an internal pore diameter of ≤240μm, a rod diameter of ≤230μm, and a high-precision layer thickness of ≤20μm.

The uniform pore distribution allows light to pass through, presenting a unique light and shadow texture while maintaining structural strength.

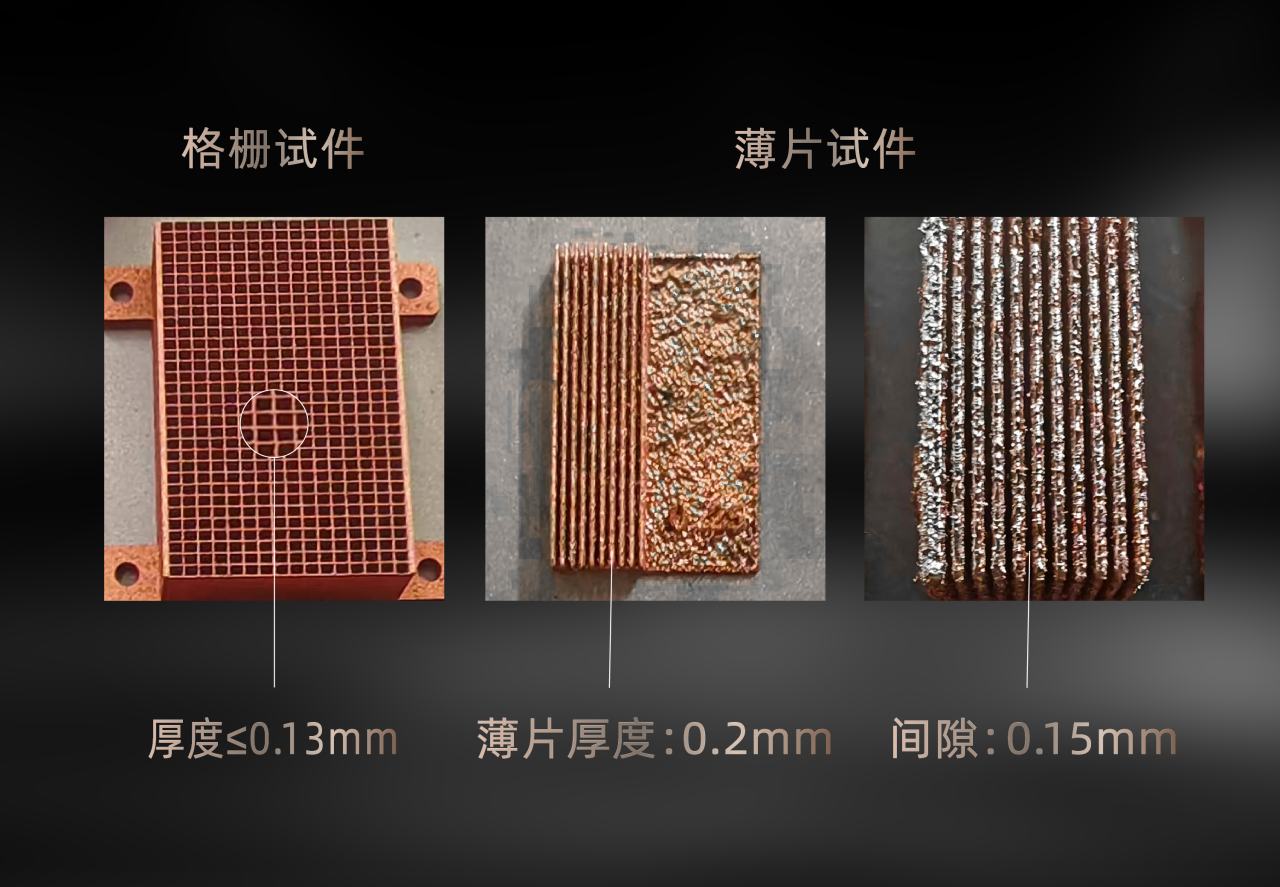

Printed pure copper grating specimens, with an internal wall thickness of no more than 0.13mm; The pure copper thin sheet specimens, with a thickness of only 0.2mm and a gap of just 0.15mm, fully demonstrate our company's exquisite craftsmanship in fine structure printing of high-reflectivity materials such as pure copper.

At present, the requirements for the performance and refinement of precision components in various industries are constantly increasing. TSC's brand-new printing process will provide users with more efficient, stable and high-quality solutions. In the future, we will continue to focus on technological research and development, constantly driving manufacturing transformation through continuous equipment iteration and process optimization, and facilitating industrial upgrading.