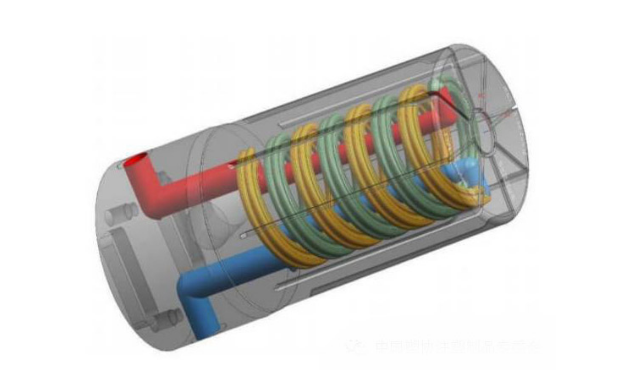

Cooling system is one of the design of mold engineering. When the plastic raw materials of the mold are heated into the mold with low temperature, the finished product can be taken after the mold is cooled. At this time, the cooling system should be relied on to cool and demoulding. The cooling system affects the demoulding time, product quality, product appearance and so on. Special shape water is designed in accordance with the product shape, the shape of the irregular cooling water. Its design is out of the traditional design position and frame, so that the water can stick to the changes of the geometry of the surface of the hole and change, not only for the mold designers to provide a larger mold design space, but also to simplify the design method of cooling water. Further, the design of the heat dissipation waterway of the mold can also use irregular shape design to improve the heat dissipation efficiency, which is the basic principle of the special-shaped waterway.

3D printing is an engineering technology that has made rapid progress in recent years. The biggest advantage of 3D printing is that the principle of 3D printing is additive manufacturing, so there is no modeling limitation. Even the complex modeling and pipelines in the object are not difficult for 3D printing, and the mold industry has noticed the value of 3D metal printing.

No matter how large the diameter of the mold waterway, or the inner corner processing that is difficult for ordinary lathes, metal 3D printing can be easily achieved. What's more, even if the planning method of the special-shaped waterway is complex, the metal 3D printing can accurately complete the mold and special-shaped waterway at the same time in just one application process.

Combined with 3D printing technology, the modified mold can bypass the top pin and fixing screws, even if the water is far away from the area, it can achieve the ideal cooling quality. The benefits of different waterways are as follows:

1. Mold design time is reduced by 75%

2. Manufacturing manpower can be saved by 50%

3. save 14% injection mold production cycle

4. Saved 16% in manufacturing expenses