LiM Laser Metal 3D Printer Builds Synergistic Optimization from Equipment to Software and Auxiliary Machines

In recent years, LiM Laser has continuously launched metal 3D printing equipment that can adapt to different production needs, and continues to provide users with comprehensive, perfect and targeted solutions. From LiM-X150A to LiM-X1500HF, they are able to meet the needs of different industries in terms of parts forming size and forming efficiency, and are well recognized by the market.

With the in-depth development and application of metal 3D printing technology in the fields of aerospace, energy and power, automobile manufacturing, mold manufacturing, etc., LiM Laser has put forward higher requirements on printing quality and process technology, etc. LiM Laser provides strong guarantee for the high quality of printing and forming of the equipment through its self-research and development of the equipment monitoring system and the intelligent alignment system of vibration mirror, etc. On the other hand, the market is looking for high-volume and large-scaled printing and forming solutions.

On the other hand, the market demand for high-volume and large-scale production is constantly rising. To ensure continuous and stable high-quality printing, LiM Laser also puts forward high-efficiency powder recycling program.

At the same time, LiM Laser is also actively researching and developing the "whole family bucket of auxiliary machines" required by the equipment, building a synergistic optimization from software to equipment and auxiliary machines to realize the development of the whole chain. Taking powder suction machine as an example, LiM-XFJ200 powder suction machine which is suitable for large-sized equipments has been launched; for small-sized equipments, LiM-XFJ10 powder suction machine with small specifications which is more convenient and easy to use has been developed to be suitable for them.

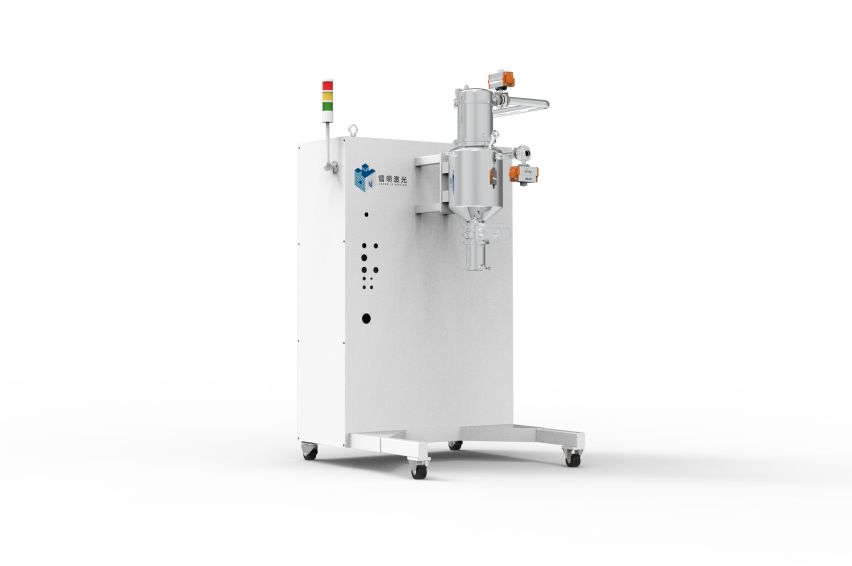

LiM-XFJ10 powder suction machine / PART 01

LiM-XFJ10 small size powder suction machine overall design compact structure, small size, with light weight, easy to move and other advantages, in the open environment, can be efficiently dealt with stainless steel, high temperature alloy powder; in the argon protection of the closed environment, titanium alloy, aluminum alloy, copper alloy, stainless steel, die steel, high temperature alloys, cobalt chrome alloy, and other materials suction powder operation; suction powder machine cables and piping connection is simple, high suction efficiency, very suitable for the powder suction machine, the powder suction machine is very convenient and easy to use. With simple cable and pipeline connection and high powder suction efficiency, it is very suitable for powder cleaning of small and medium-sized metal 3D printing equipments of LiM Laser.

Although the size of the suction machine is small, it is set with the functions of cartridge blowback, pressure detection, valve position detection, vibration falling powder, material level detection, etc., which can effectively guarantee the safety in the process of using; when clearing the powder and suctioning it under the closed environment of argon protection, the powder bin detects the pressure and oxygen content and interacts with the suction machine through the aerial insertion, which can guarantee the safety in the process of working.

This powder suction machine can be compatible with our 10L powder barrel, LiM-BFQ15/BFQ40 pump powder to be used as a receiving tank, can realize the powder fast recycling, versatility, good adaptability.

LiM-XFJ200 powder suction machine / PART 02

The existing LiM-XFJ200 powder suction machine needs to complete the powder suction operation under the argon protection and closed environment, with higher vacuum degree, used with large-scale laser laser large-scale metal 3D printing equipment, also has the functions of pressure detection, valve position detection, material level detection and so on.

The auxiliary machine can be used with large-capacity LiM-BFQ200 pump powder, and after printing, LiM-XFJ200 powder suction machine can be used to realize powder clearing and powder recycling; the recycled powder will flow into LiM-BFQ200 pump powder after sieving treatment for reuse.

On the basis of deep plowing in the research and development of metal 3D printing equipments, LiM laser aims at the development of the whole chain, through the development and customization of equipment auxiliary machines and software systems, LiM laser provides users with synergistic and integrated solutions to make manufacturing more efficient.