In fields such as aerospace and automotive manufacturing, lightweight design is a key factor in enhancing product performance, reducing energy consumption and strengthening competitiveness. With the vigorous development of metal 3D printing technology, re-conceiving and optimizing the structure of components from the perspective of additive thinking has become an important path to promote the realization of lightweight, high performance and high reliability of products. With its profound technological accumulation and industry experience, TSC helps users achieve the goal of lightweight and weight reduction of components by means of process methods such as topology optimization and lattice structure.

Topological optimization is a structural design method that calculates the optimal material distribution through mathematical means, which can achieve higher design freedom and obtain a larger design space. Metal 3D printing technology combined with topology optimization not only reduces the processing difficulty of components but also minimizes material usage to the greatest extent while meeting mechanical properties, achieving the goal of weight reduction.

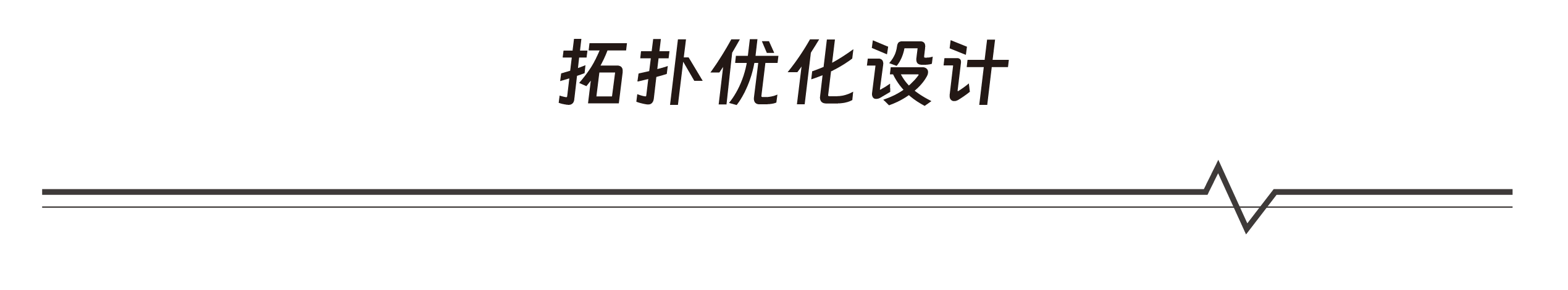

Part size: 420mm×90mm×70mm

Printing material: Titanium alloy (TC4)

This part is a typical topological optimization component printed by the LiM-X400 device. Compared with the solid structure design, its weight has been significantly reduced, and its mechanical properties and structural utilization rate have been greatly improved, fully demonstrating the technical advantages of "topological optimization +3D printing".

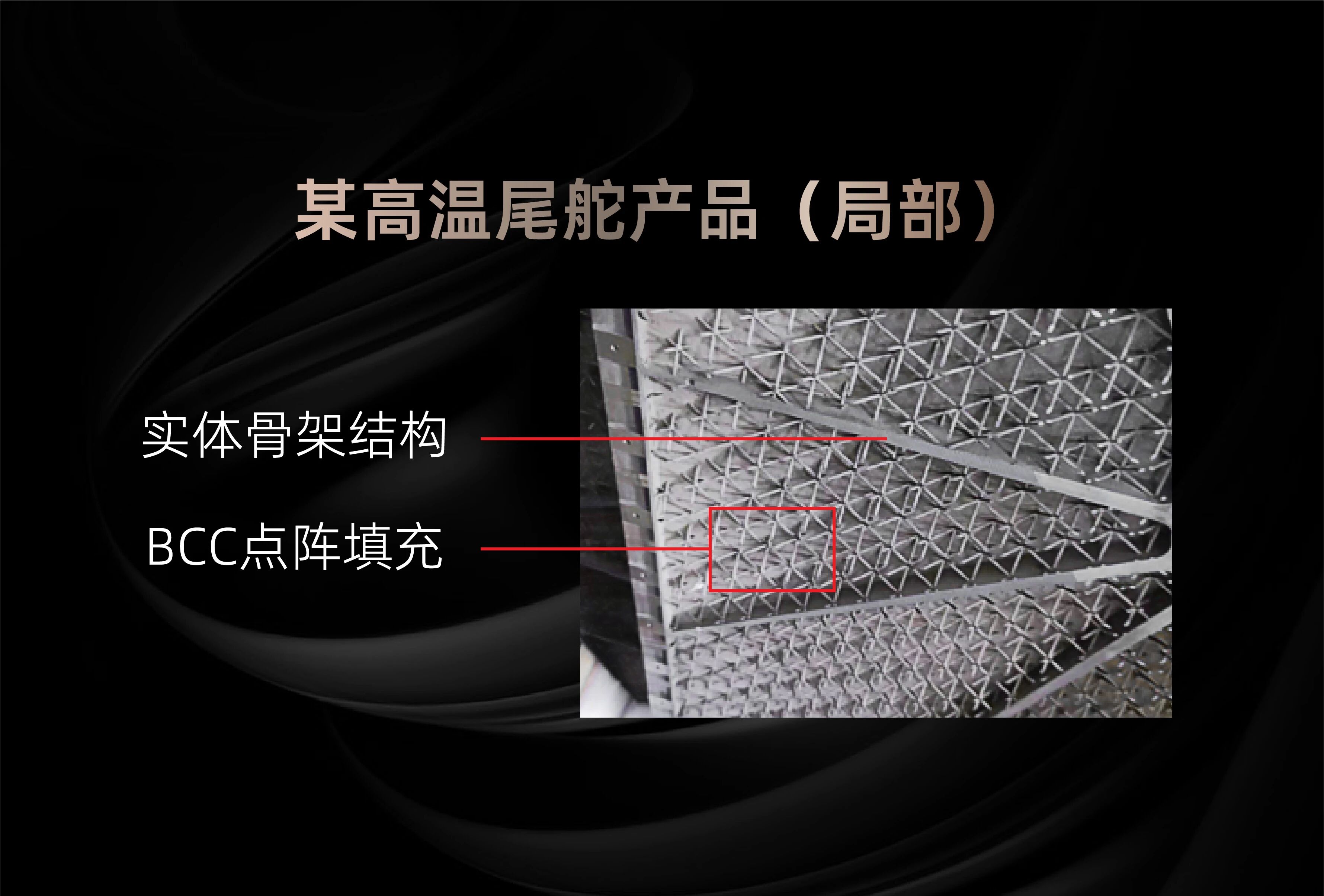

In addition, adding a BCC lattice structure is also a commonly used lightweight method. Take a certain satellite bracket manufactured by Xinjinghe as an example. The internal microstructure of this part is filled to achieve a lightweight design. Under the condition of ensuring the performance requirements for use, the weight is reduced by more than 40%. Such processes and structures have passed various verifications and have formed complete and comprehensive process specifications.

A certain satellite support (partial)

The phase change energy storage device involved in manufacturing adopts a three-dimensional lattice + thin-walled skin structure design. The skin thickness is only 0.5mm, and the rod diameter of the lattice structure is 0.5mm. It is prone to deformation during processing, and the interior is a closed cavity and complex lattice, which cannot be achieved by traditional manufacturing processes. The product is directly formed by metal 3D printing, featuring high dimensional accuracy. While reducing weight by 40%, the production cycle is shortened by 60%. At present, this part has passed the aerospace process appraisal and entered the model application.

Three-dimensional lattice + thin-walled skin structure

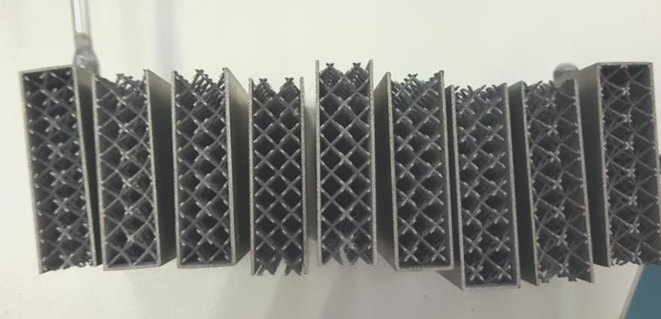

In practical applications, topology optimization and BCC lattice filling are often used in combination to optimize the design of components. Under the premise of ensuring the structural strength and rigidity of key parts, materials are removed from non-critical areas, and lattice structures with lower relative density are used to replace the solid parts with lower stress levels in the topological structure, thereby further achieving weight reduction while maintaining the performance of components.

Take a certain high-temperature tail rudder product printed by TSC as an example. This component adopts a composite structure design of three-dimensional frame + dot matrix + thin-walled skin. First, geometric reconstruction is carried out through topological optimization to determine the solid skeleton with load-bearing capacity. Based on the optimized form, BCC dot matrices are widely filled in non-load-bearing or low-load-bearing areas to ensure that the product meets the lightweight requirements while maintaining good mechanical properties and overall connection stability.

A part of a high-temperature tail rudder

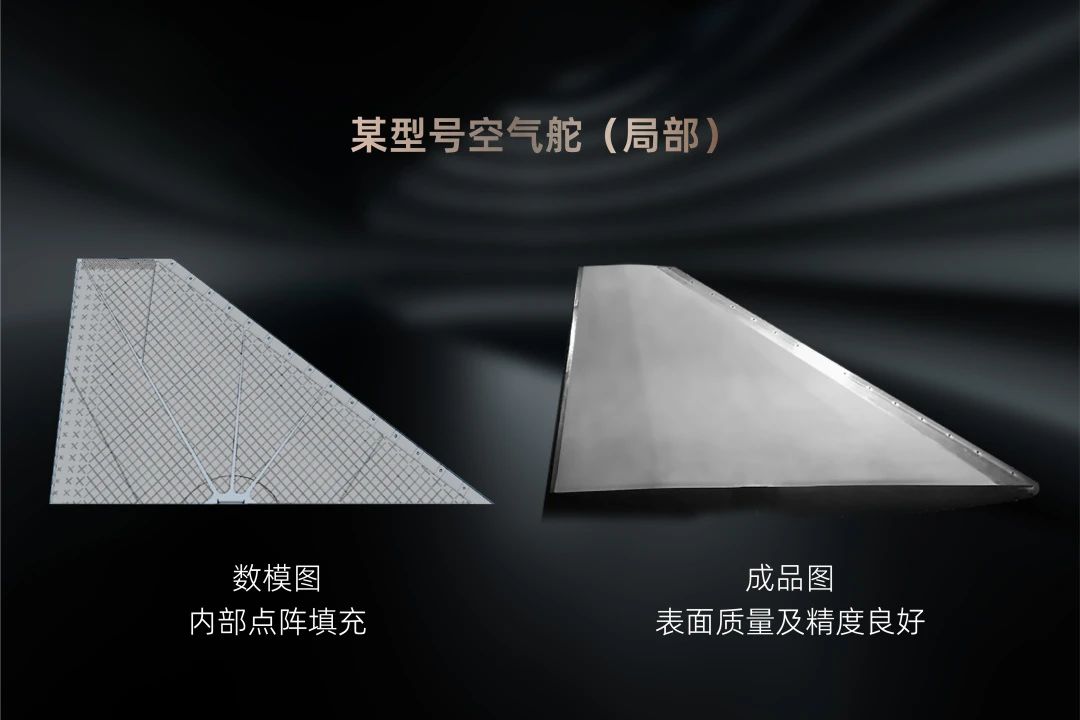

In addition, the air rudder parts of a certain model printed by TSC feature a typical thin-walled sandwich structure, which ensures structural strength and performance in the form of "skeleton + skin", reducing weight by over 40%. Manufactured by metal 3D printing technology, the finished product has good surface quality and dimensional accuracy, and the structural stability meets the design requirements.

At present, the application of metal additive manufacturing technology is becoming increasingly in-depth. The additive thinking of design first leading the research and development and manufacturing of key components has become the mainstream direction of development in various industries. TSC has been deeply engaged in the field of metal additive manufacturing for many years, constantly breaking through the limitations of traditional processes. With new processes, new technologies and new equipment, it provides users with key support and innovative impetus, helping more users in various fields break through manufacturing bottlenecks and accelerate development and transformation.