From May 27th to 29th, 2025, the Turbine Technology Conference and Civil Aviation Engine and Gas Turbine Exhibition were held in Suzhou. This event was carried out in a dual-wheel drive mode of "technical conference + innovation exhibition". TSC showcased a number of innovative achievements in metal 3D printing, presenting the company's cutting-edge technologies in the field of aviation power and gas turbines from a comprehensive perspective.

At the conference site, Wang Chenchen, a pre-sales engineer from TSC, delivered a keynote speech titled "Application of Metal Additive Manufacturing in the 'Two Engines' Field", presenting the key technical advantages of metal 3D printing technology in breaking through the development bottlenecks of domestic large aircraft, civil aviation engines and heavy-duty gas turbines from the perspectives of technical principles, process demonstrations and material applications. It also shared the innovative applications and typical cases of TSC Metal's 3D printing technology in fields such as aerospace.

In the field of manufacturing large-sized and complex components for aerospace, TSC exhibited the high-strength aluminum cabin sections printed and formed by the LiM-X650 equipment, with the workpiece size being φ566mm×600mm. The appearance, metallographic, mechanical and other properties of this part are good. The structure was enhanced through topological optimization design, and the lattice structure was integrated to meet the lightweight requirements, demonstrating the process advantages of TSC Metal 3D printing technology in the one-piece forming of complex structures.

Cabin section

The aero engine exhaust component printed by the LiM-X400 equipment has a size of 430mm×430mm×180mm. The design of this part integrates typical features such as large size, thin wall, and irregular curved surface structure. It is manufactured in an integrated manner using metal 3D printing technology, significantly shortening the processing cycle.

Aeroengine exhaust assembly

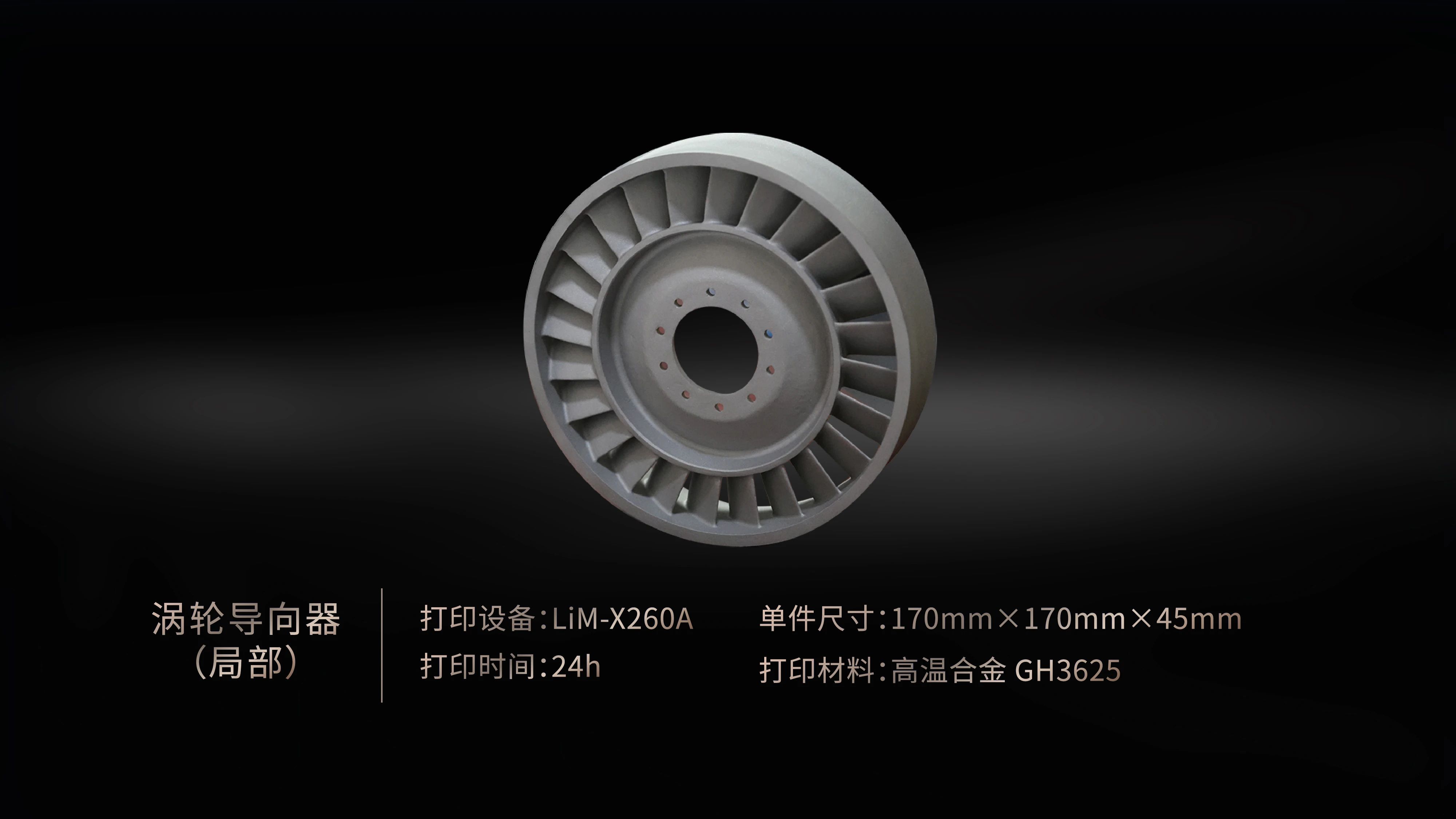

In addition, TSC also showcased the turbine guide (partial) printed by the LiM-X260A equipment. This part has a cascade ring structure and is made of high-temperature alloy GH3625 material. It breaks through the limitations of traditional manufacturing processes, realizes integrated manufacturing, and significantly improves the overall performance of the part.

Turbine guide (local)

TSC's self-developed metal 3D printing equipment has been well tested by users for a long time, providing strong support for high-quality, efficient and batch production of components in fields such as aerospace. It has participated in many national engineering projects and has been repeatedly tested. In the new-generation manned spacecraft test vehicle project, the LiM-S2510 laser near-net-shape forming equipment was used to print the heat-resistant large bottom frame of the re-entry capsule with a diameter of 3.95m, solving the problem of "deformation and cracking" of large integral components. The effects were outstanding in improving manufacturing accuracy, increasing manufacturing dimensions, and enhancing production efficiency. The material utilization rate has increased by 67%, significantly enhancing the efficiency of subsequent assembly.

Heat-resistant outsole frame of the re-entry capsule

During the development process of the Tianwen-1 Mars probe mission, more than 30 products of the LiM-X series laser selective melting equipment were manufactured and delivered, and 9 products of the LiM-S series laser near-net-shape forming equipment were manufactured and delivered. In the Blue Arrow Aerospace Tianque series liquid oxygen and methane rocket engine project, the TSC LiM-X400 and LiM-X650 equipment batch-printed a variety of key components, contributing to significant progress in the Tianque series engines in terms of structural integration and improvement of thrust performance.

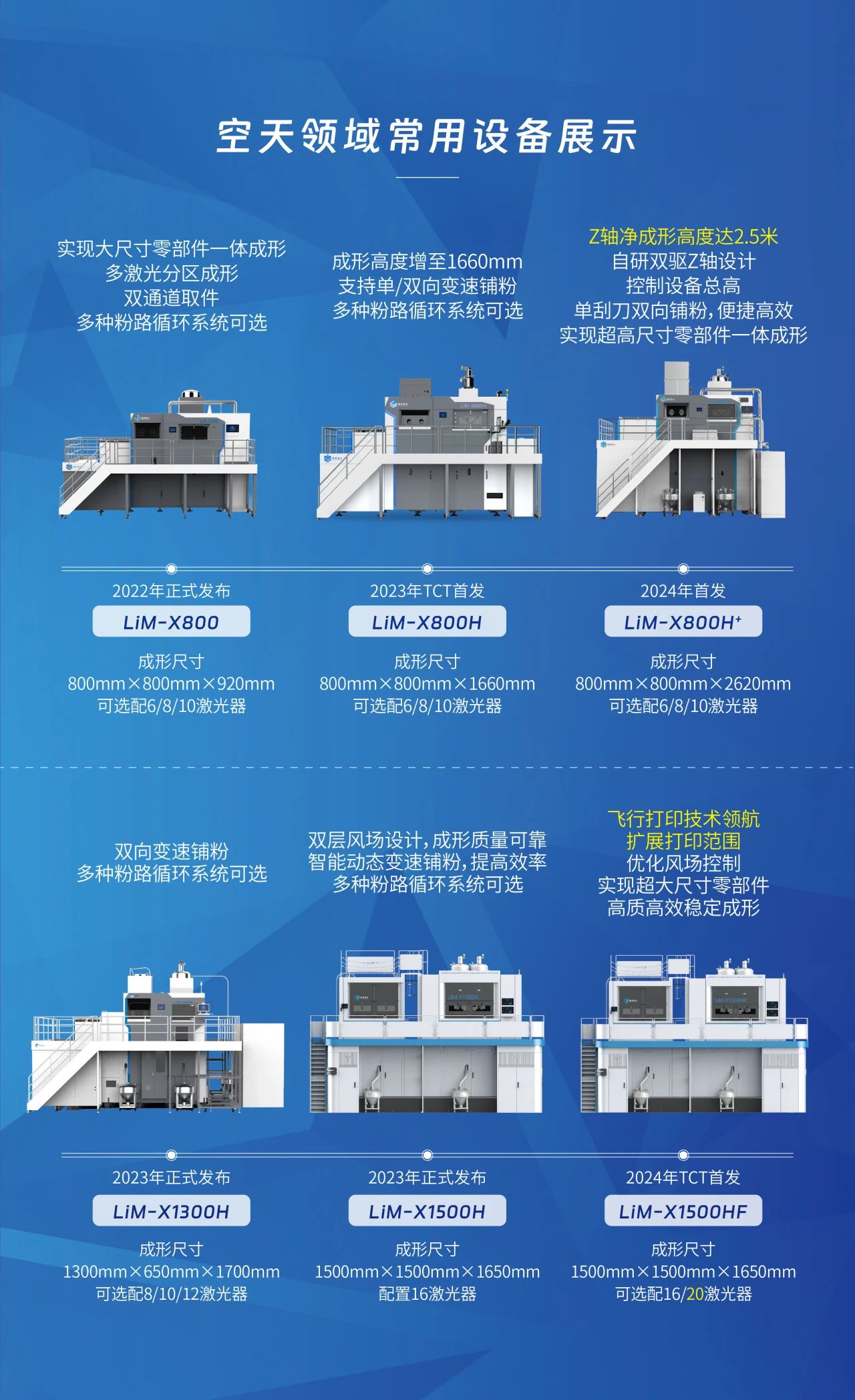

As a pioneer in the metal 3D printing industry, TSC has extensive experience in the research and development and manufacturing of metal 3D printing equipment, customized product printing services, structural optimization design, and process technology development. This can effectively accelerate the research and development and trial production of aerospace products, speed up design iterations, and optimize performance advantages. At present, TSC has launched more than ten types of LiM-X series SLM equipment. The forming area ranges from 150mm to 1500mm, and the net forming height exceeds 2500mm. The reliability and stability of the equipment have been widely verified through market applications.

In the future, TSC will continue to promote the in-depth integration of metal 3D printing technology into industries such as aerospace, energy and power, and automotive manufacturing, helping more users achieve the goals of cost reduction, efficiency improvement, and quality enhancement.