A space optical imaging system refers to a system that uses optical equipment in space to observe and study space and the Earth, mainly including space telescopes and Earth observation remote sensing systems. Recently, the 508 Institute of the Fifth Academy of China Aerospace Science and Technology Corporation, in collaboration with Shanghai Jiao Tong University, innovatively proposed to use metal 3D printing technology to complete the forming and preparation of the support structure of suspended mirrors in space optical systems, in response to the lightweight support requirements. TSC's subsidiary, LiM Laser, provided crucial equipment support for this research.

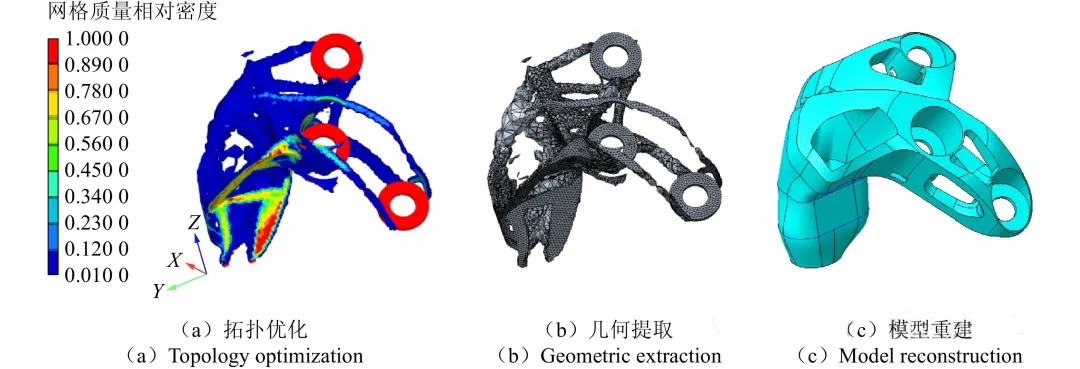

The support structure of this suspended mirror adopts a cantilever vertical support scheme, and the entire mirror assembly is placed at the top of the calibration mechanism. To ensure the safe operation of the bottom movable mechanism, its total mass must be strictly controlled below 17 kilograms. In response to this demanding design requirement, the research team carried out topological optimization on the mirror support structure. By refining the unit mesh, the optimization accuracy was significantly improved.

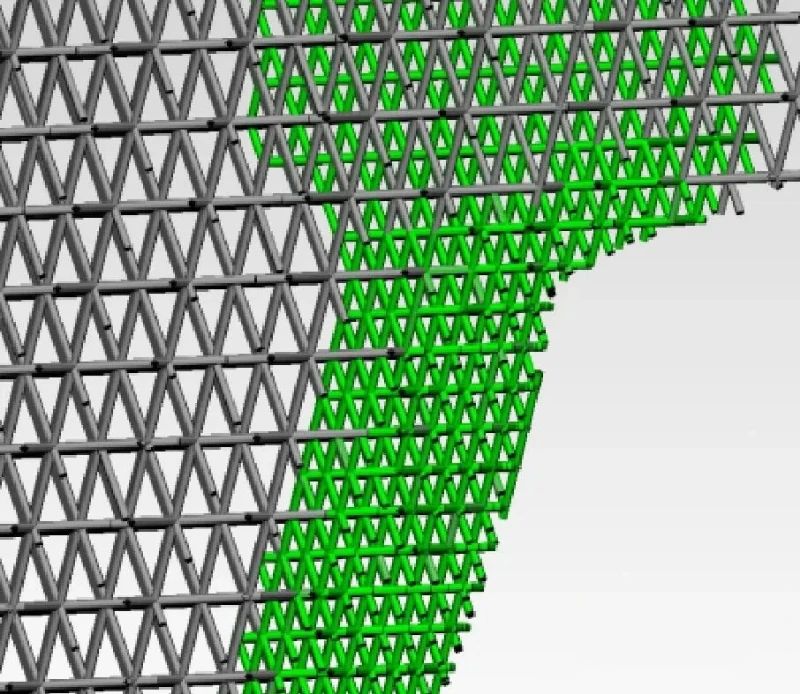

After iterative optimization, the final determined reflector support structure scheme is as follows: the skin thickness is 0.8mm, the BCC lattice size is 6mm × 6mm × 6mm, and the rod diameter is 0.6mm. In local stress concentration areas (such as base installation holes and suspension elbow points), a 3mm × 3mm × 3mm dense dot matrix was added. Local reinforcing ribs were added at the weak positions of the base, effectively enhancing the rigidity of the base.

The final designed 3D printed mirror support structure weighs only 6.5 kilograms, keeping the total weight of the entire mirror assembly at 16.5 kilograms. The finite element model simulation analysis of the entire component was conducted, and the results showed that all indicators met the corresponding requirements.

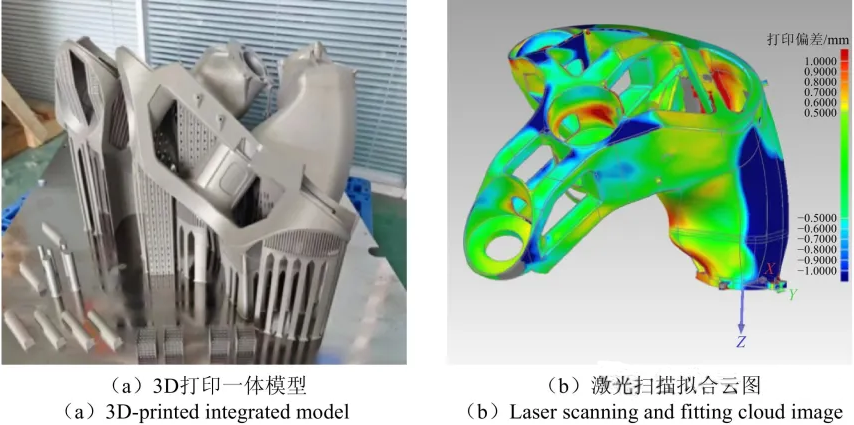

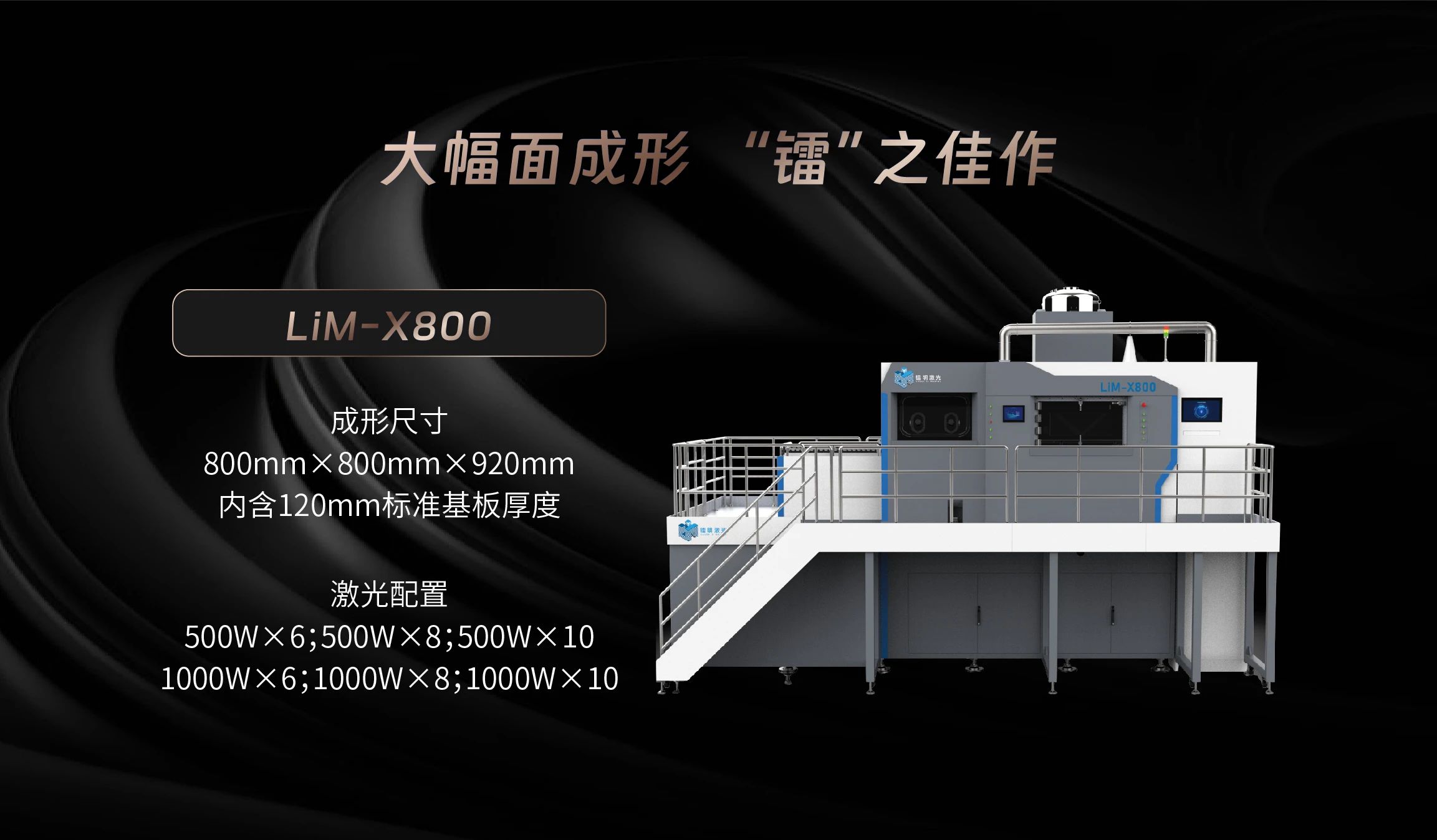

The metal 3D printing equipment of the subsidiary, LiM Laser, has provided a strong guarantee for the smooth progress of the research. The team researchers used the LiM-X800 device to integrally print and form the mirror support structure made of titanium alloy. After inspection, the maximum global deformation of the printed product is 1.5mm, and the deformation at the processing position is less than 1mm, both within the processable range.

The printed support structure was applied to the mirror assembly for actual testing. The results showed that the mirror rotation Angle before and after the test was less than 6 ", and the rigid body displacement was less than 0.02mm. All these changes were within the range of optical assembly and adjustment errors. The test results show that the 3D printed support structure has stable mechanical properties and high specific stiffness, successfully solving the stiffness matching and lightweight design problems in the suspension support of irregular-shaped mirrors, and providing an innovative solution for the space optical load support system.

The LiM-X800 equipment adopts a three-station structure design for forming, powder cleaning and part retrieval, and is easy to operate. The equipment is standardly equipped with 6 lasers, and users can freely choose to select 8 or 10 lasers. Its long-lasting filtration system is equipped with a back-blowing function and uses long-lasting filter elements with a lifespan of over 100,000 hours, ensuring a continuous and uninterrupted printing process. The equipment can be equipped with a powder bed monitoring system to monitor the quality of each layer of powder spreading and the quality of melting and solidification in real time, significantly enhancing the stability of the printing process and enabling the efficient preparation of workpieces that meet the requirements.

Metal 3D printing equipment, as a typical innovative representative of future industrial mother machines, plays a significant role in accelerating the research and development, trial production and design iteration of products in high-end manufacturing fields such as aerospace and energy power. This successful participation in the forming and preparation of the space mirror support structure has further expanded the application scenarios of metal 3D printing technology in the aerospace field. In the future, we will continue to leverage our technological advantages, relying on high-quality equipment and excellent technical services, to help users in more fields achieve breakthrough progress.