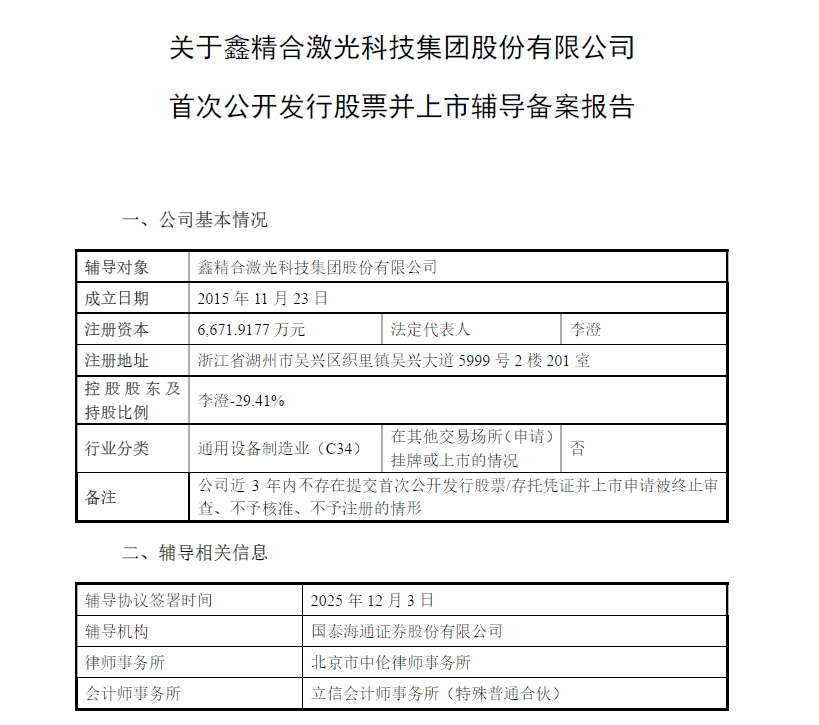

On December 22, 2025, TSC Laser Technology Group Co., LTD. (hereinafter referred to as "TSC") officially completed the filing for listing tutoring, marking a crucial step for this national-level "little giant" enterprise specializing in niche markets into the capital market.

TSC's compound annual growth rate has maintained a long-term upward trend. Its technological advantage lies in its ability to form high-precision and complex structural parts in one go, which is particularly suitable for the strict requirements of the aerospace field for lightweight and high-strength components. The technical advantage in the field of laser metal Deposition (LMD) lies in its large-scale and high-efficiency additive manufacturing and repair capabilities, which stand out in the manufacturing and maintenance of large-scale equipment in the energy sector.

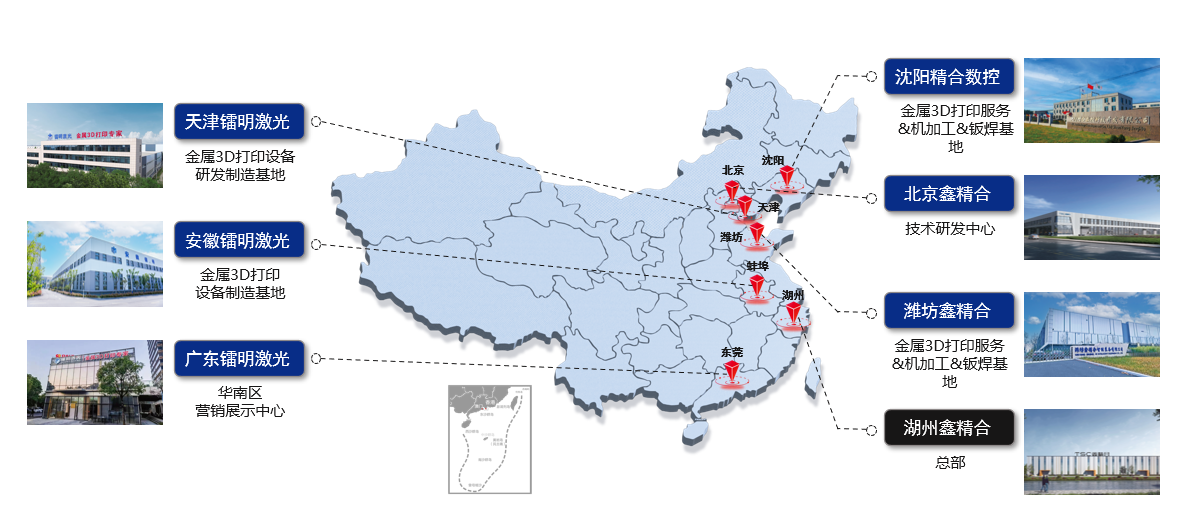

TSC has established a complete strategic layout: with Huzhou as its headquarters, radiating to the two major R&D bases in Beijing and Tianjin, consolidating the production and processing foundation in Shenyang, Weifang and Deyang, relying on the additive equipment assembly base in Anhui to improve the manufacturing chain, and taking Guangdong as the marketing hub for consumer goods to link the market. With its strong technological capabilities and industry influence, the company has successively won many significant honors such as the "One-Stop" demonstration enterprise for industrial foundation strengthening by the Ministry of Industry and Information Technology and the Golden Bridge Award. It has been successfully included in the list of national key specialized, refined, distinctive and innovative "Little Giant" enterprises for two consecutive terms. At the same time, it deeply participates in the formulation of national and industry standards, empowers the standardized development of the additive manufacturing industry through standardization construction, and continuously contributes the strength of a leading enterprise.

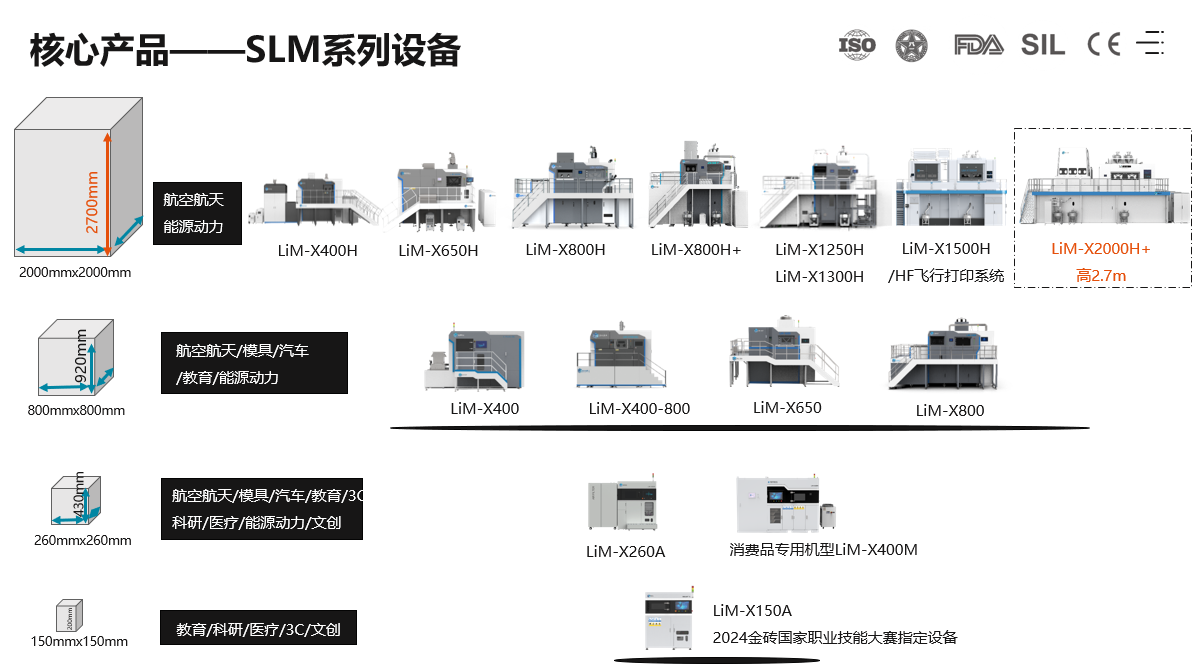

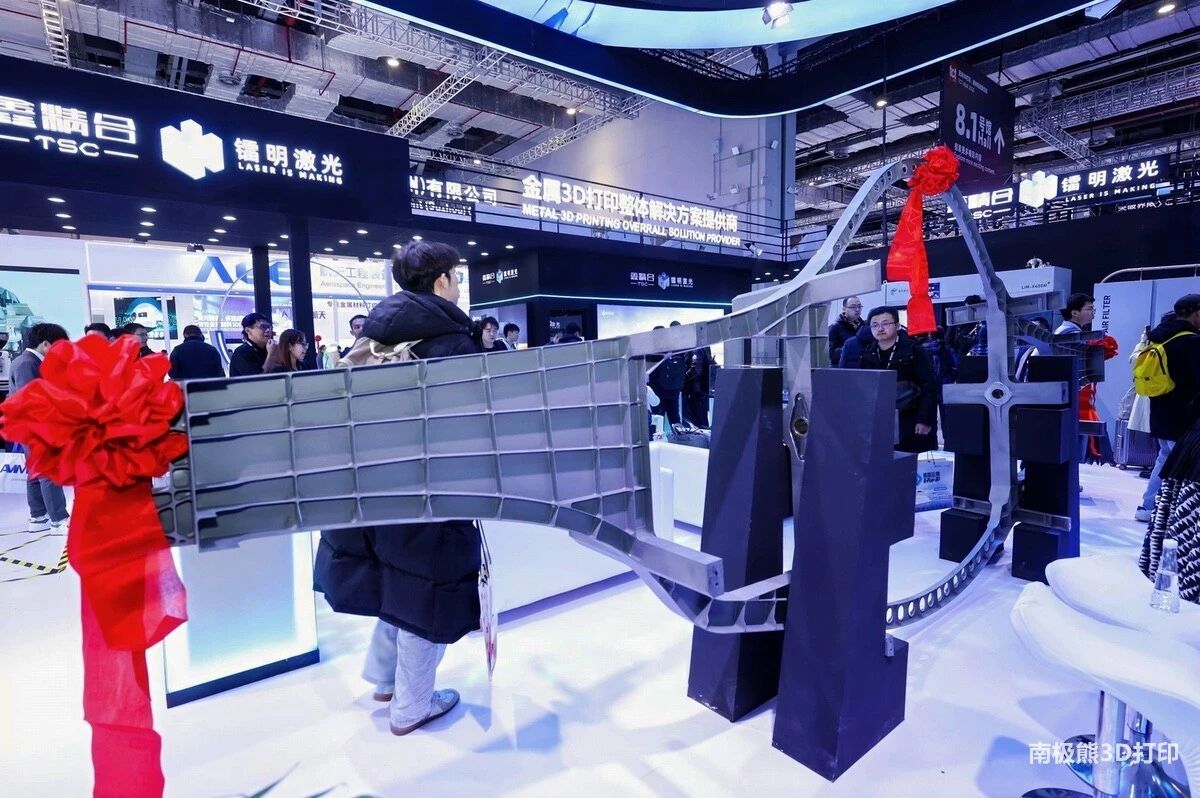

As a leading enterprise deeply engaged in the field of metal 3D printing for over a decade, since its establishment in 2015, it has built a full industrial chain layout covering "material research and development - equipment manufacturing - process innovation - product delivery". TSC's self-developed additive manufacturing equipment has formed a full product matrix from LiM-X150A to LiM-X2000H+, with forming dimensions ranging from 150mm to 2000mm, comprehensively covering different application scenarios of small, medium and large sizes. It has reached the international advanced level in the printing process of special materials such as titanium alloys, superalloys, aluminum alloys, high-strength steel and copper alloys. With these cutting-edge technologies, TSC has been deeply involved in major national projects such as Chang 'e-4, Tianwen-1, and the return capsule of manned spacecraft, providing key metal components for over 30 types of aerospace equipment and becoming a core supplier in the high-end manufacturing field of aerospace. In the civilian sector, its technological achievements have been widely applied in multiple industries such as automotive manufacturing, mold production, medical implants, and energy and power, achieving a leap from "prototype manufacturing" to "mass production".

The company holds over 300 patents and has achieved multiple technological innovations and industrialization breakthroughs.

In terms of equipment innovation, TSC focuses on core modules such as multi-laser applications, wind farm system optimization, mechanical structure and precision control, and software algorithm iteration. Through continuous printing verification and technological breakthroughs, it has successfully overcome common technical challenges in the industry, including low precision and insufficient stability in multi-laser optical path splicing, limited efficiency in low-layer thick forming, and poor performance in large-sized forming. The independently developed "flight printing" technology has pioneered the mobile galvanometer module lap calibration control to achieve seamless multi-laser splicing. The dust removal and double-layer wind field design effectively eliminate the problem of black slag in the wind field, laying a solid foundation for the breakthrough of ultra-large format printing technology. The laser heating solution breaks the traditional processing boundaries. It uses a 9000W high-power multi-mode laser to heat the powder of the current layer in real time, significantly enhancing the density of the parts. It is particularly suitable for the stable forming requirements of materials prone to cracking such as titanium alloys and refractory metals. In addition, the continuous implementation of a series of innovative technologies such as the self-developed LiM-X400 automated production line, the fully automatic powder circulation system, and the green laser printing solution has provided core technical support for the industrial-scale application, high-efficiency production, and high-quality delivery in the additive manufacturing industry, demonstrating the technological innovation hard power of leading enterprises.

In terms of process innovation, TSC relies on intelligent software to incorporate forming simulation into the process design stage, effectively enhancing the success rate and accuracy of printing. Overcome the forming difficulties of thin-walled lattice structures and stably achieve ultra-lightweight high-rigidity structures with a wall thickness of 0.5mm and a rod diameter of 0.5mm. The small-angle unsupported process enables large-scale printing of parts from 15° to 35°, reducing the reliance on supports. The fine structure printing scheme ensures that the surface roughness is less than Ra 3.2μm and the accuracy is within ±0.05mm. Pure copper and other high-reflectivity materials are stably formed. After annealing, the electrical conductivity reaches 94.4%IACS, with excellent thermal conductivity and a porosity of less than 0.14%. Developed the process parameters of ALSi7Mg and CuNi30, and introduced beam shaping technology to enhance efficiency. By integrating laser selective melting and cladding technologies, multi-material composite manufacturing (such as copper alloy matrix + high-temperature alloy strengthening layer) is achieved, taking into account both strength and performance.

TSC is deeply rooted in the national strategic orientation, taking technological innovation as the core engine to drive the iterative upgrading of the industry. It focuses on the technological breakthroughs and industrialization breakthroughs of domestic multi-laser large-size additive manufacturing equipment, injecting strong impetus into the large-scale development of new quality productivity in the manufacturing industry. We continuously improve the core indicators of equipment reliability, stability and consistency, precisely match the comprehensive demands of multiple fields in terms of forming dimensions, processing efficiency, printing accuracy and long-term operation and maintenance, and constantly expand the application boundaries of the industry and deepen the value of scene empowerment. Facing the global technological frontier and the main economic battlefield of the country, the company has always been committed to the strategic development direction of the country, deeply engaged in key fields such as aerospace, served the major demands of the country with its solid technological strength, empowered core customers in the industry with customized solutions, and helped China's high-end manufacturing industry climb to the top of the value chain.