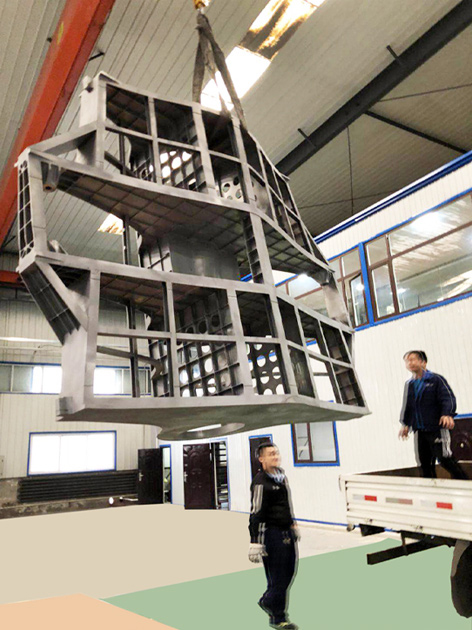

This structure adopts the inverted trapezoid structure layout, and is an integral closed frame structure, the material is TA15 titanium alloy. The product structure is complex, mainly composed of two - sided frame lattice frame and other typical structures. The overall size of the product is large, integrated forming. The integrated main structure of the metal frame and beam has a total length of 7XXXmm, a width of 2XXXmm and a height of 1XXXmm.Using laser deposition manufacturing technology, special connection technology, new stress reduction technology, advanced scanning technology and other high-tech means, can realize tens of meters of frame beam integrated manufacturing, after manufacturing to ensure that the overall structure deformation control within 0.5 mm. Through a large number of theoretical research and process experiments, the group has broken through many advanced manufacturing technology problems such as LMD, WAAM and LW, and the comprehensive mechanical properties of product materials have reached the forging level, which indicates that China has the ability to mass produce the integrated main structure of frame and beam.

Short cycle: the overall structure of the product is complex and the precision requirement is high. The traditional process takes two years to open the mold casting, but the advanced manufacturing technology of Finishing Group can be completed in 6 months, reducing the manufacturing cycle by 75%.

Low cost: a series of tedious processes such as traditional die casting and forging and processing are eliminated, and the cost is reduced by 50%. The utilization rate of raw materials reaches more than 95%, which actively responds to the overall green development requirements of national intelligent manufacturing.

Agile manufacturing: the realization of design while manufacturing, while ensuring the overall performance and production cycle, to maximize the customization requirements of designers, avoid the traditional process of repeated mold opening, solidified design ideas, prolonged manufacturing cycle and other drawbacks;

Excellent performance: The comprehensive application of a variety of advanced manufacturing technologies can meet the design requirements of super complex structure, high precision and lightweight, and effectively solve the problems of large weight, low precision and poor mechanical properties of traditional manufacturing process products. The integrated main structure of the frame and beam has strong overall stiffness, light weight and excellent comprehensive performance.