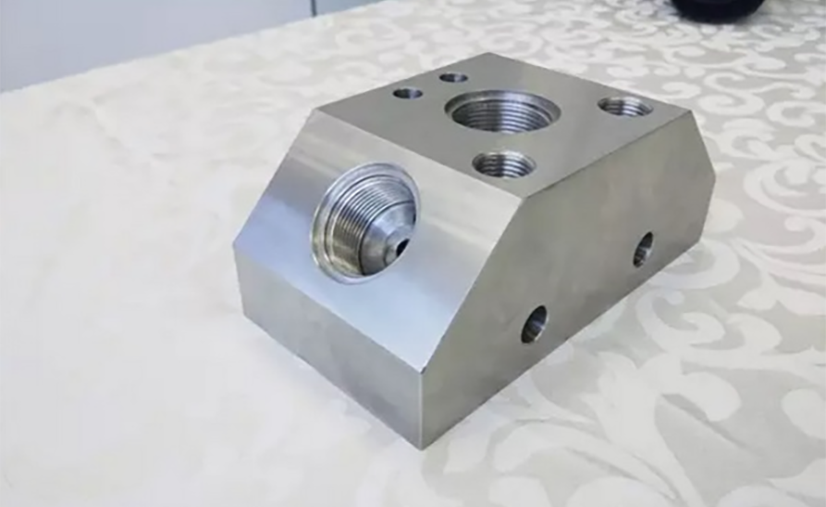

TSC has achieved significant progress in "Research on Key Technologies of Metal 3D printing applied to nuclear power". Our research group successfully manufactured complex flow valve body of nuclear power plant with Selective Laser Melting (SLM) 3D printing technology. After the basic performance test, the material chemical composition and basic mechanical properties of the valve body meet the requirements of the international nuclear power standard RCC-M. The engineering application of this part will achieve a breakthrough in the application of metal 3D printing manufacturing parts in the field of nuclear power.

The body length is 140mm, width is 76mm, height is 56mm. The material is Z2CND17-12 (316L stainless steel), which is commonly used in nuclear power. The internal flow channel is complex and the requirement is high. If the traditional manufacturing process is used, it requires integral forging and precision machining, and the manufacturing cycle is long and the process is complex. The project adopts SLM technology, using laser layer by layer scanning curing metal powder, gradually stacking out of the valve body shape and complex internal flow channel, one time forming, saving materials and improving component stability, compared with the traditional process can shorten the manufacturing cycle, and can meet the requirements of small batch rapid production, reduce costs and so on.