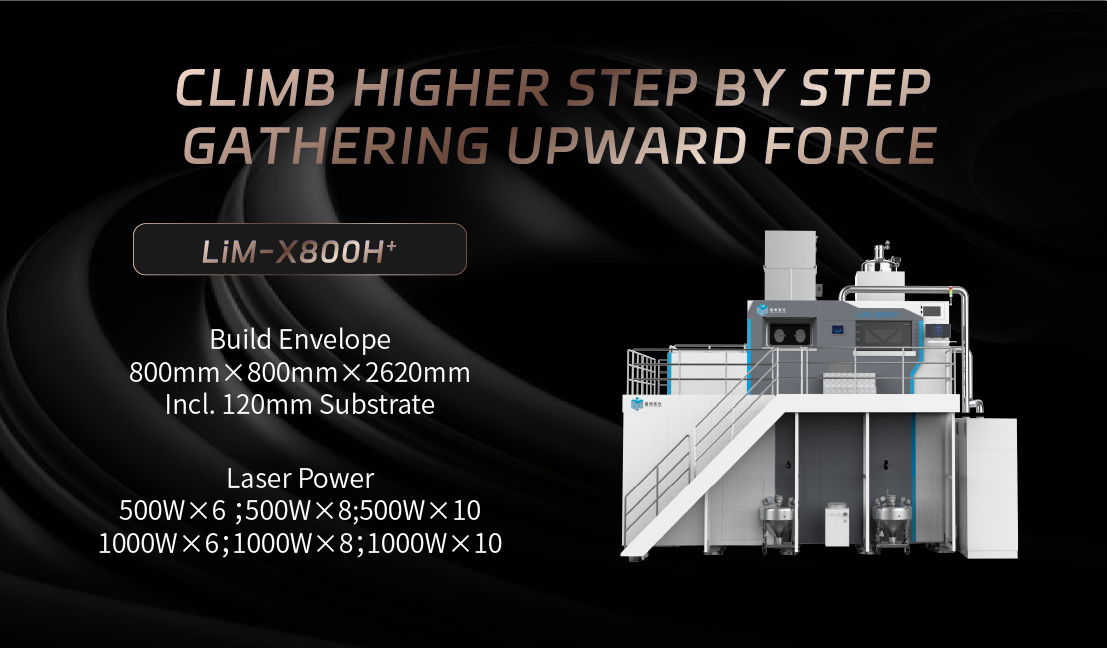

Metal 3D printer forming height refresh! The laser LiM-X800H+ device is released with a Z axis net forming height of 2500mm

In 2023, the company will launch LiM-X800H equipment for large-format, high-size forming needs in high-end manufacturing fields such as aerospace and automotive. Over the past year, on the basis of user verification and feedback, LiM Laser integrated production experience and launched LiM-X800H+ with higher forming space, providing better solutions for users in the aerospace field to print and manufacture large parts.

01. High size, break the routine

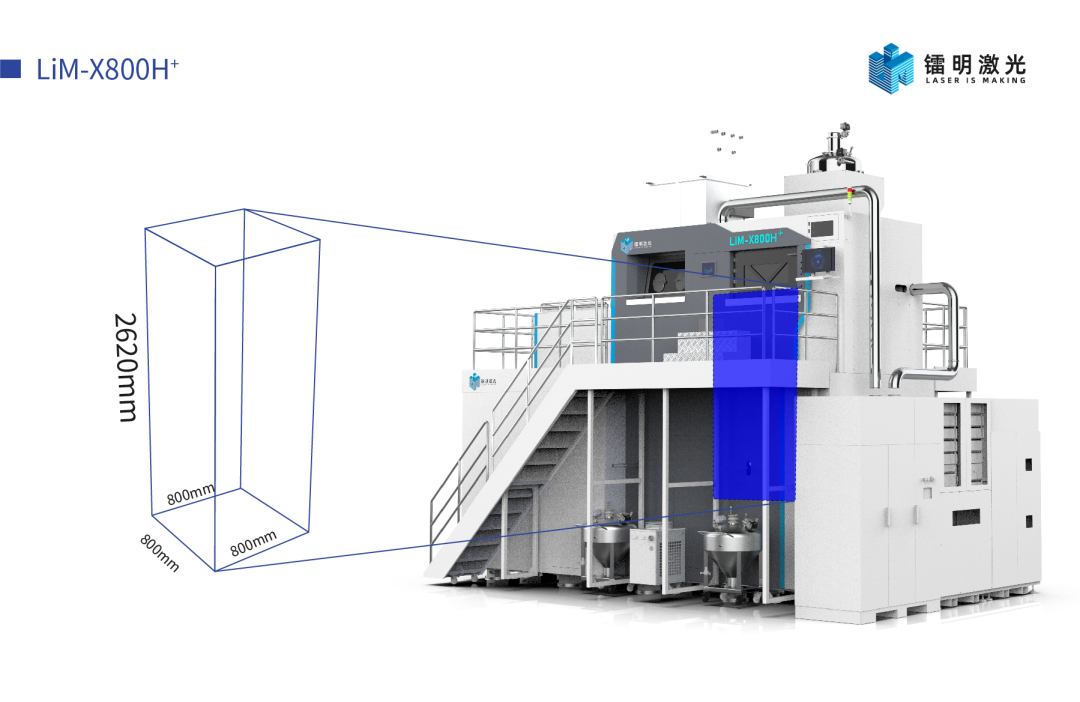

LiM-X800H+ net forming height of 2500mm, compared to the same class of products, the forming height is significantly improved, for aerospace and other fields, can further meet the large size parts integrated forming or mass production needs.

02." Small "stature, total height controllable

LiM-X800H+ fully considers the installation conditions of the user, using the laser self-developed dual drive Z-axis design, 4 guide rails and high-precision dual drive synchronous control, effectively reduce the height of the equipment, the total height is only 7m, support most of the layout design of the factory.

03. Multi-laser, efficient printing

LiM-X800H+ comes with 6 lasers as standard, and 8 and 10 lasers can be freely selected according to demand. The forming efficiency is ≥150cm³/h, ≥200cm³/h, ≥250cm³/h, and the production efficiency is stable and guaranteed.

04. Single scraper, spread powder in both directions

The higher the forming size of the component, the more printing layers, and the higher the requirements for powder laying speed. LiM-X800H+ uses a single scraper bidirectional powder laying technology, compared to the double scraper design, single scraper leveling is easier and more convenient; The bidirectional powder laying strategy can shorten the time of powder laying while ensuring the quality of powder laying, and the efficiency of powder laying can be increased by about 60% compared with one-way powder laying.

05. High quality, stable shape

The metal 3D printing process will produce a lot of slag and dust, which will affect the printing quality. Self-developed high uniformity and high stability wind field structure design, improve the uniformity of large format LiM Laser printing, to ensure LiM-X800H+ high quality and stable production capacity.

06. Multiple models, rich choice

LiM Laser has rich and mature experience in the development and manufacturing of high-size metal 3D printing equipment, and has previously released five large-format, high-size equipment: LiM-X400H, LiM-X650H, LiM-X800H, LiM-X1300H, LiM-X1500H solutions.

Among them, the forming size of LiM-X1300H equipment is 1300mm×650mm×1700mm, and the standard is 8 lasers, 10 and 12 lasers are optional.

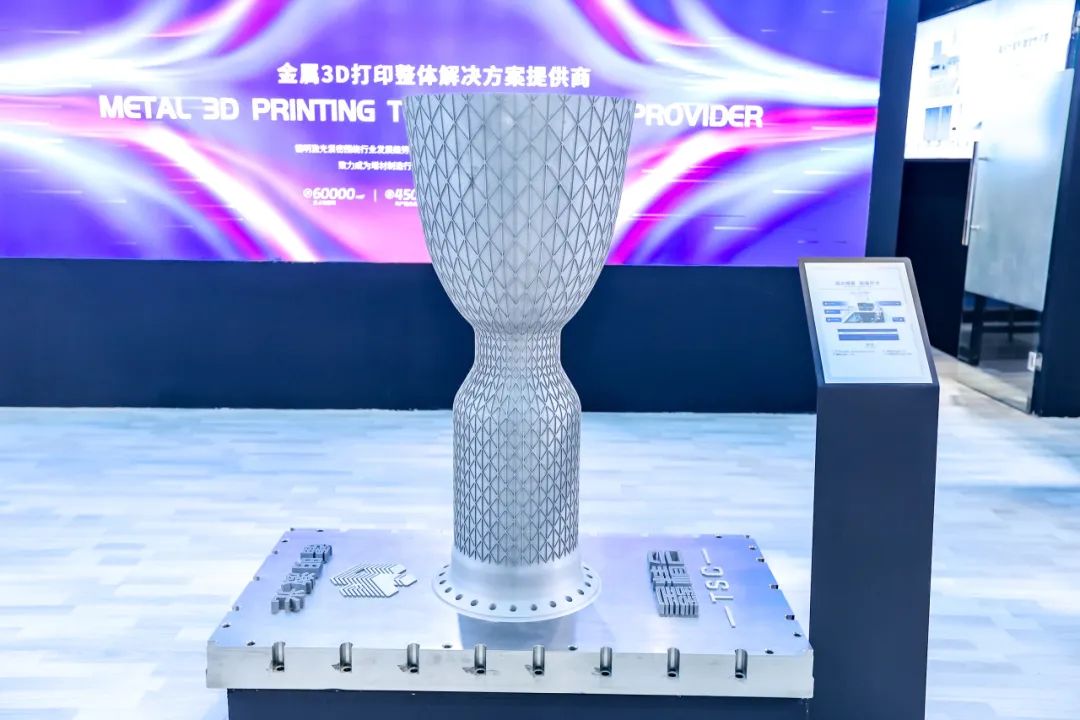

Thrust chamber: The part size is 589mm×589mm×1357mm, using LiM-X1300H equipment integrated forming manufacturing, no solder joints, higher structural strength; Internal runner size accurate, good finish; The external texture is more consistent with the design requirements, and the process stability is high, showing the good process of high size printing of LiM Laser.

The field of metal additive manufacturing has always maintained a rapid development trend, larger forming format, higher forming space, faster forming speed, each upgrade will bring greater productivity improvement to the entire manufacturing industry. LiM Laser continues to deeply cultivate metal 3D printing technology to enable technology and make manufacturing more efficient. In the future, we will still give full play to our own experience and advantages to provide users with more innovative solutions to help reduce costs, increase efficiency and improve quality.