Metal additive manufacturing technology, as the core driving force reshaping the modern industrial landscape, is deeply integrating into the core manufacturing links of key fields such as aerospace, energy and power, and automotive manufacturing. The Xinjinghe LiM-X800 series of large-sized metal 3D printing equipment, with its super-large forming space, breakthrough process innovation and production stability, effectively addresses the core challenges of large and complex components in terms of manufacturing accuracy, production efficiency and comprehensive cost, providing a driving force for large-scale industrial manufacturing.

Meanwhile, the rapid development of national strategic industries such as aerospace, shipping and rail transit has put forward higher requirements for the comprehensive performance, processing accuracy and production efficiency of large-scale metal 3D printing equipment, directly promoting the rapid development and iteration of equipment with specifications of meter level and above.

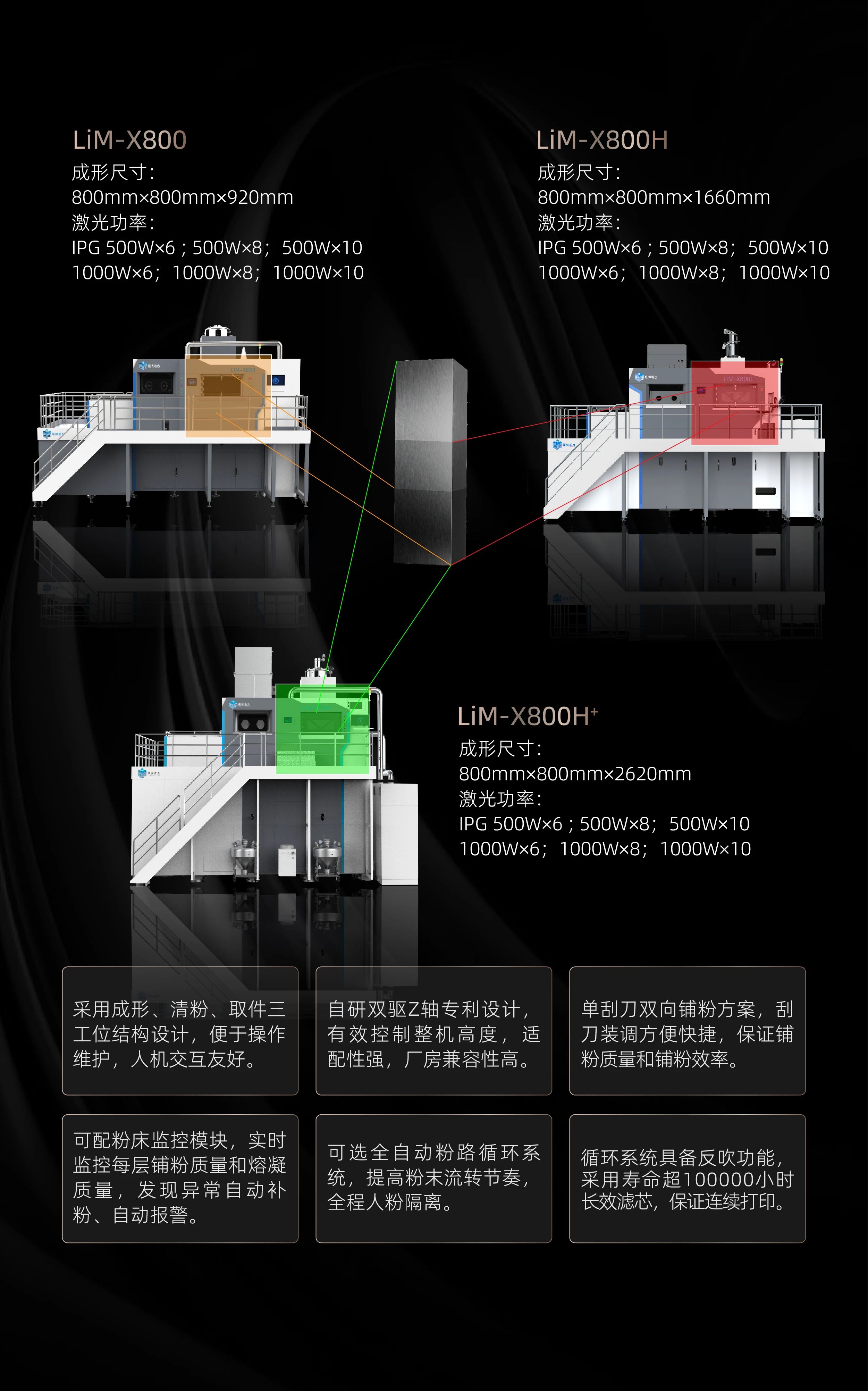

After years of technological accumulation and product development, Xinjinghe has formed a relatively complete equipment matrix with a forming area of 800mm×800mm. The LiM-X800 equipment was first launched in 2022, providing strong equipment support for the manufacturing of components in the aerospace and automotive manufacturing fields. In 2023, the LiM-X800H equipment made its grand debut at the TCT ASIA exhibition. Focusing on the forming requirements of large-sized long-axis parts, the forming height of the equipment was increased to 1660mm (including a standard substrate thickness of 80mm). In 2024, based on in-depth market insights, the meter-level equipment LiM-X800H+ was launched, with a Z-axis net forming height of up to 2500mm, achieving integrated manufacturing of ultra-large-sized components and providing a superior solution for super-large and long-axis parts in the aerospace industry.

In the field of aerospace component manufacturing, the LiM-X800 series equipment effectively addresses the manufacturing challenges of large and complex components in terms of forming dimensions, processing accuracy, and comprehensive performance.

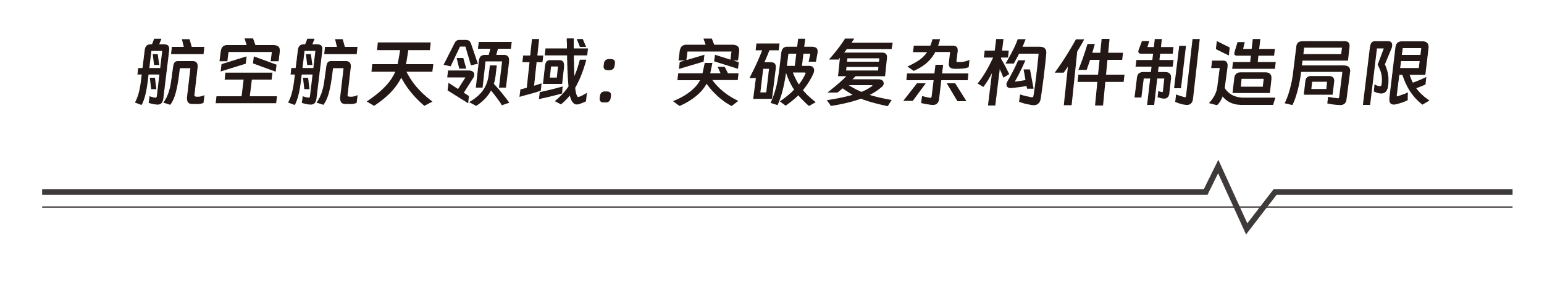

Xinjinghe relies on the large-sized LiM-X800H equipment to manufacture high-temperature alloy aero-engine pre-rotating nozzles (φ754mm×151mm). This part adopts a large-volume lattice structure design, precisely removing the solid structure in non-critical areas to achieve the goal of lightweighting.

For such large-sized thin-walled components with complex lattice cavities, traditional manufacturing processes are difficult to process, have high losses, and it is even more difficult to ensure the integrity and consistency of the structure. Metal 3D printing solutions can be formed in one piece without molds, significantly simplifying the production process, improving material utilization, and effectively controlling the overall cost. The precise lattice structure of the pre-swirl nozzle provides excellent energy absorption characteristics, making it particularly outstanding in dissipating the impact and shock loads brought by the high-speed airflow of the engine, and providing reliable performance guarantees for aviation critical components.

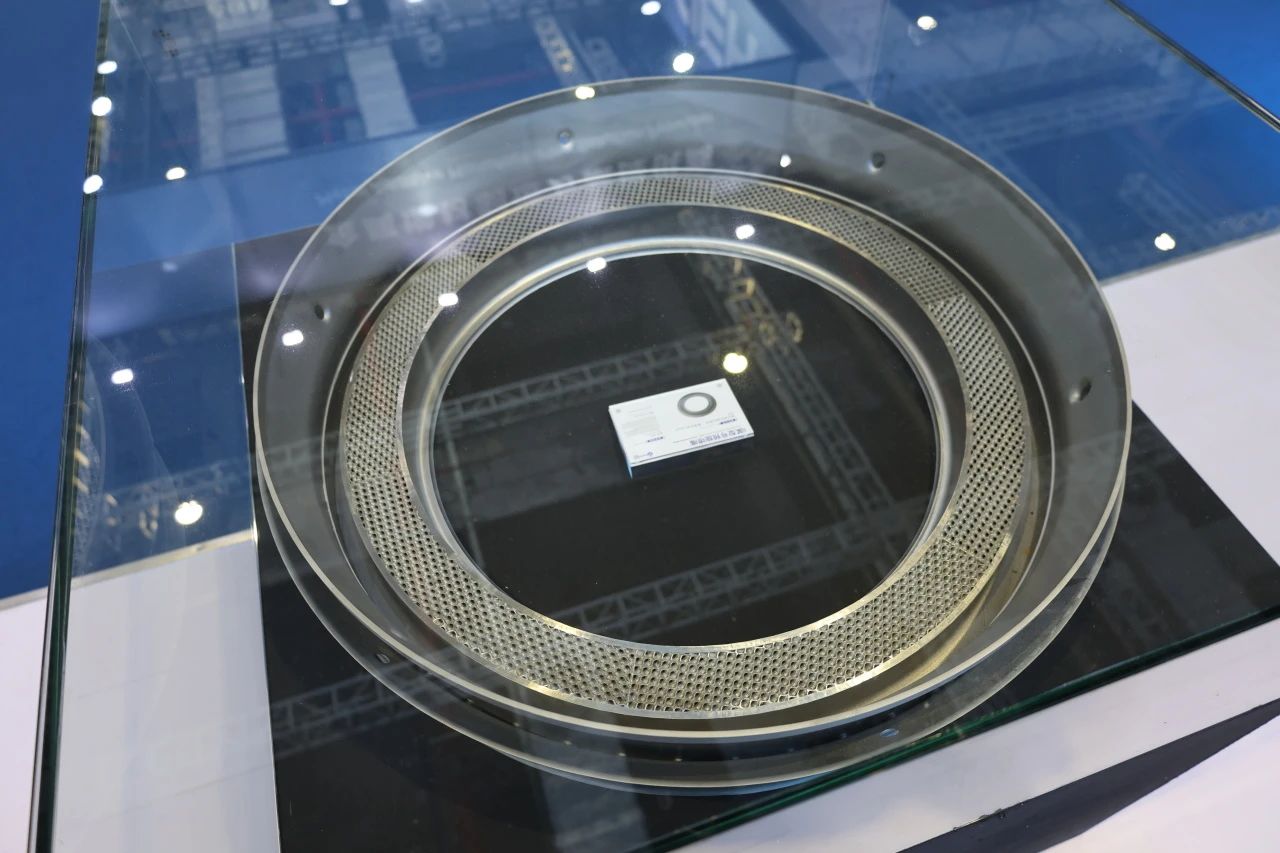

The LiM-X800H equipment is used to print the key component of an aero engine, the casing (φ715mm×300mm). This part is made of high-temperature alloy material and features an integral ring-shaped structure. It is large in size and has a complex profile. It is characterized by thin walls and weak rigidity. The final product has excellent fluid dynamic performance, high strength and good durability.

The 3D printing method is adopted for forming, which overcomes the processing difficulties of high-strength materials such as high-temperature alloys in traditional processes, simplifies the cumbersome processing procedures, and directly prints to form. This not only significantly improves the material utilization rate but also greatly accelerates the research and development speed of aerospace components, achieving rapid optimization and iteration of design schemes.

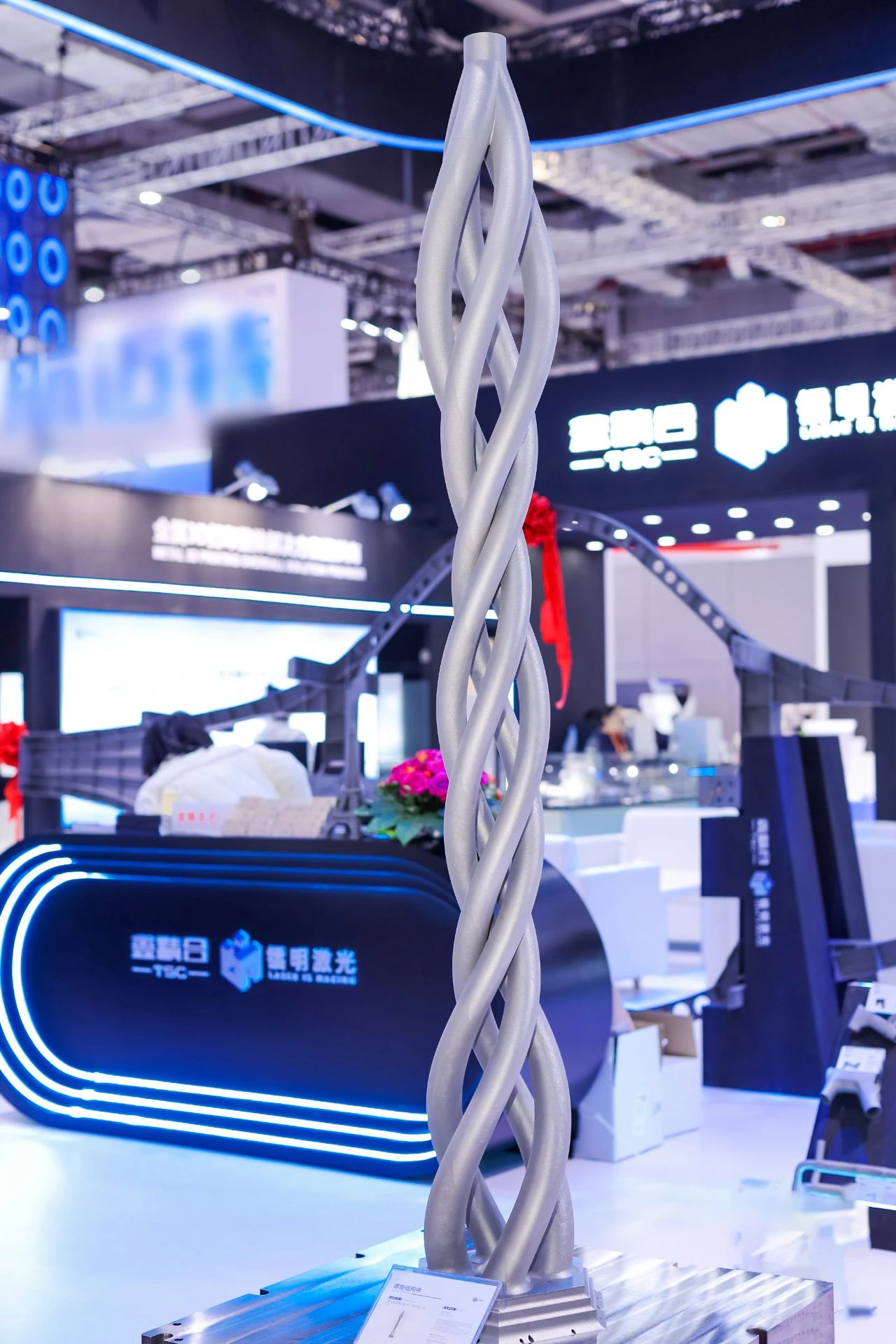

Based on the excellent performance of LiM-X800H, the net forming height of the Z-axis of LiM-X800H+ has been broken through to 2.5m, and the height of the formable components has been further increased. The equipment successfully printed ultra-high spiral structural components with dimensions of 418mm×362mm×2210mm. This part is made of lightweight and high-strength TA15 titanium alloy material. While ensuring the strength performance of the part, its weight is only 22kg.

The LiM-X800H+ can be continuously and stably printed for 305 hours in one piece, fully demonstrating the process stability and reliability of the equipment. It provides a strong technical verification for the rapid manufacturing of super-sized and lightweight structural components in industries such as aerospace and large molds.

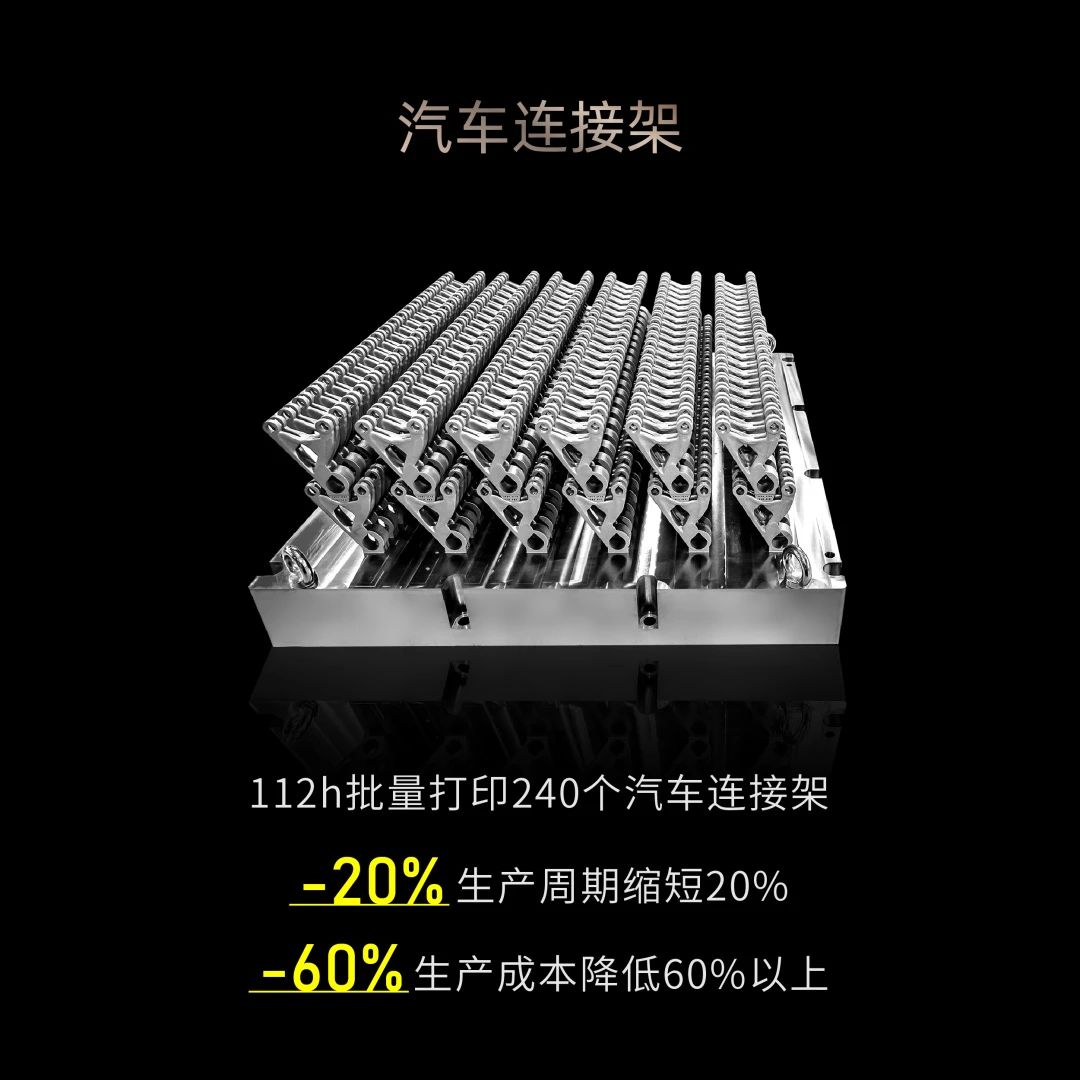

In the manufacturing of automotive parts, the car connection frame printed in full format by the LiM-X800 customized equipment demonstrates the significant advantages of metal 3D printing technology in large-scale mass production. The overall dimensions of this component are 770mm×790mm×235mm (excluding the substrate), and the individual dimensions are 42mm×115mm×131mm. By adopting an 80μm large-layer thickness process, 240 automotive connection frames were printed and manufactured in just 112 hours, achieving efficient multi-layer batch printing. The production cycle was shortened by 20%, and the production cost was reduced by more than 60%. LiM-X800 realizes the integrated printing and forming of high-performance automotive connection frames, helping to increase production and improve efficiency of spare parts in the automotive manufacturing field.

Meanwhile, the high flexibility of 3D printing technology enables it to demonstrate more advantages in the design and development stage of automotive parts: breaking free from the limitations of traditional processes and granting great freedom to design; It can be directly manufactured without mold opening, compressing the prototype verification cycle from "weeks" to "hours", greatly reducing the development cost of repeatedly verifying and iterating parts. While achieving rapid manufacturing, it ensures the precision and flexibility of the products.

The LiM-X800/800H/800H+ equipment, through continuous technological iteration and innovative application, constantly breaks through the manufacturing limitations of large and complex metal components, providing efficient, precise and economical additive manufacturing solutions for strategic industries such as aerospace and automotive manufacturing. In the future, Xinjinghe will continue to focus on the research and development of large-sized metal 3D printing equipment. With more advanced technology and more reliable products, it will provide more efficient and stable solutions for high-end manufacturing, driving industrial innovation and high-quality development.