As a subversive new technology, metal additive manufacturing can effectively improve production efficiency and give rise to new momentum for industry development. The pursuit of processing efficiency and quality in modern manufacturing industry is constantly improving. As a pioneer in the metal 3D printing industry, LiM Laser in order to meet the demand for high quality and high efficiency in various industries, has been upgrading and iterating its equipments, and continuously focusing on the program of production efficiency improvement.

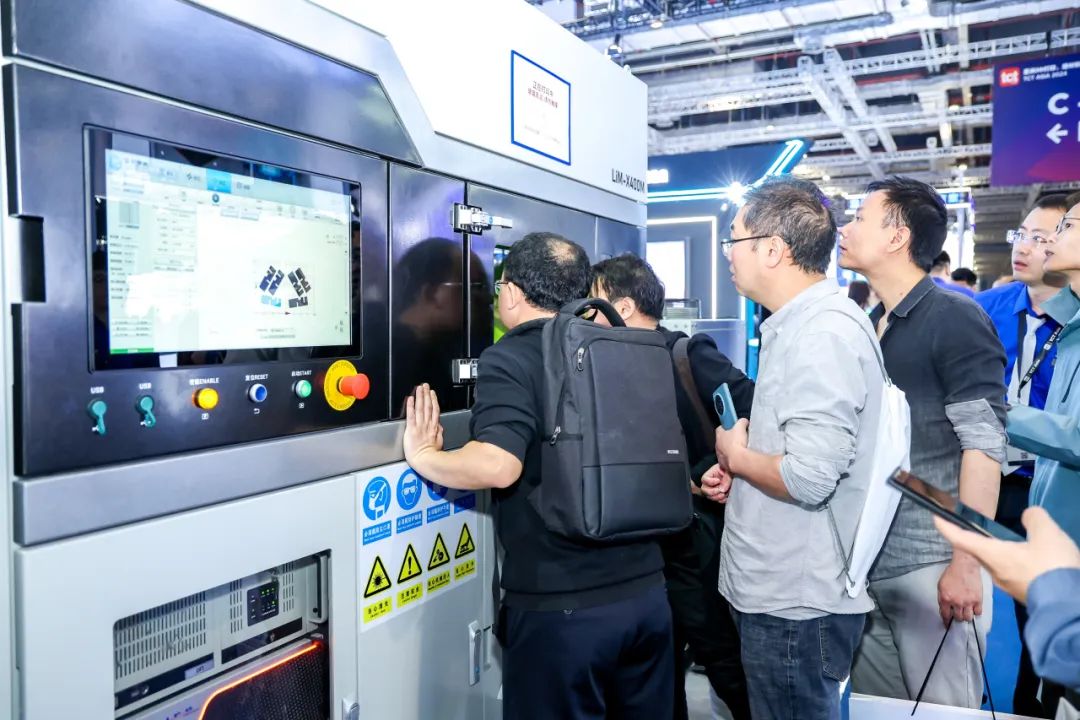

In this year's TCT, LiM Laser the first LiM-X400M machine to be equipped with two 3000W ultra-high-power lasers, has a printing layer thickness of up to 0.4mm, which further improves the production efficiency.

LiM-X400M equipped with 3000W lasers attracted much attention.

High energy, greatly improved productivity

Compared with the conventional 500W laser version of LiM-X400M, the forming efficiency of the 3000W laser (multimode) equipment has increased significantly. taking steel parts as an example, the layer thickness of printing with a 500W laser is generally no more than 0.1mm, and with the 3000W laser printing solution, the layer thickness can reach 0.4mm. in the actual printing process, the large layer thickness forming solution will significantly In the actual printing process, the large layer thickness forming program will significantly save the powder spreading time for large-size parts, and at the same time, the overall forming efficiency is also increased from about 0.3kg per hour to about 1.7kg per hour, which is about a 5-fold increase in efficiency.

Laser Power | 500W | 3000W |

Support steel printing layer thickness | ≤0.1mm | ≈0.4m m |

Single light forming efficiency | ≈0.3KG/h | ≈1.7KG/h |

Multi-mode lasers: Multi-mode lasers are lasers that simultaneously produce light emitted from two or more modes. Compared with single-mode lasers, the spot size is large, the divergence angle is large, but the beam quality is poor; and because of the existence of a variety of frequency modes, the frequency stability is relatively poor, and is mainly used in applications that do not require high frequency accuracy.

Two modes to meet more application needs LiM-X400M equipment equipped with 3000W multi-mode laser, can also be adjusted to single mode, the output power is still 500W, both with large layer thickness printing ability to realize the rapid manufacture of large-size blank parts; but also be able to carry out the regular layer thickness printing, the manufacture of more complex structure, surface roughness of the finer parts, a device to meet the needs of a variety of applications. One device to meet the needs of a variety of applications.

Printing application practice

3000W laser prints mold test parts

The material of the part is 18Ni300, if use conventional 500W laser equipment printing, it takes about 240min; 3000W laser printing molding time is only 40min, molding efficiency is significantly improved.

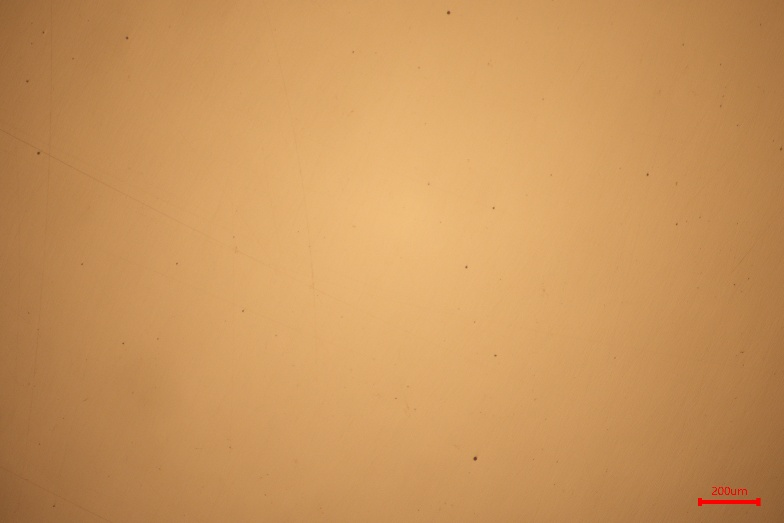

The densities of the parts are good, and the metallographies of the parts are shown in the figure below:

Metallography - transverse

Metallography - longitudinal

“The world's martial arts, only fast and unbreakable”. Under the fierce competition in the market, improving efficiency is the only choice for transforming the development. In the field of mold manufacturing, if the traditional machine processing method is used to manufacture large-sized molds, the processing time is long and the processing difficulty of internal runners is large; the selection of high-power, large-layer-thickness metal 3D printing equipment for processing and manufacturing can quickly and efficiently realize the one-piece forming manufacturing of such molds.

Customization is one of the advantages of LiM-X series of equipment. Take LiM-X400M equipment as an example, it can customize the power and quantity of laser according to the actual application requirements. As an advanced enterprise in the metal 3D printing industry, LiM Laser is committed to providing personalized and customized metal 3D printing solutions from the actual demand, helping users to transform to high efficiency and intelligence. In the future, we will continue to focus on market dynamics, constantly optimize and upgrade process equipment, and continue to provide solutions and inspiration to increase production and improve efficiency, so as to empower the development of the industry.