In recent years, aerospace applications have been demanding continuous development towards high performance, high efficiency, high reliability and low cost. The design of related components also requires them to be lighter, stronger and more integrated. Traditional manufacturing processes are facing dual challenges of forming efficiency and performance stability for complex large components.

TSC has over ten years of experience in the in-depth customized production of aerospace components, a complete technology research and development system, and a well-tested equipment matrix. We are well aware that the pain points in manufacturing large-sized and over-specification components lie not only in "making big", but also in "making precise and stable". Therefore, a series of ultra-meter-level equipment represented by LiM-X1500H, which have been verified through engineering applications, have been developed, and systematic additive manufacturing solutions are provided.

Multi-laser collaboration achieves efficient forming

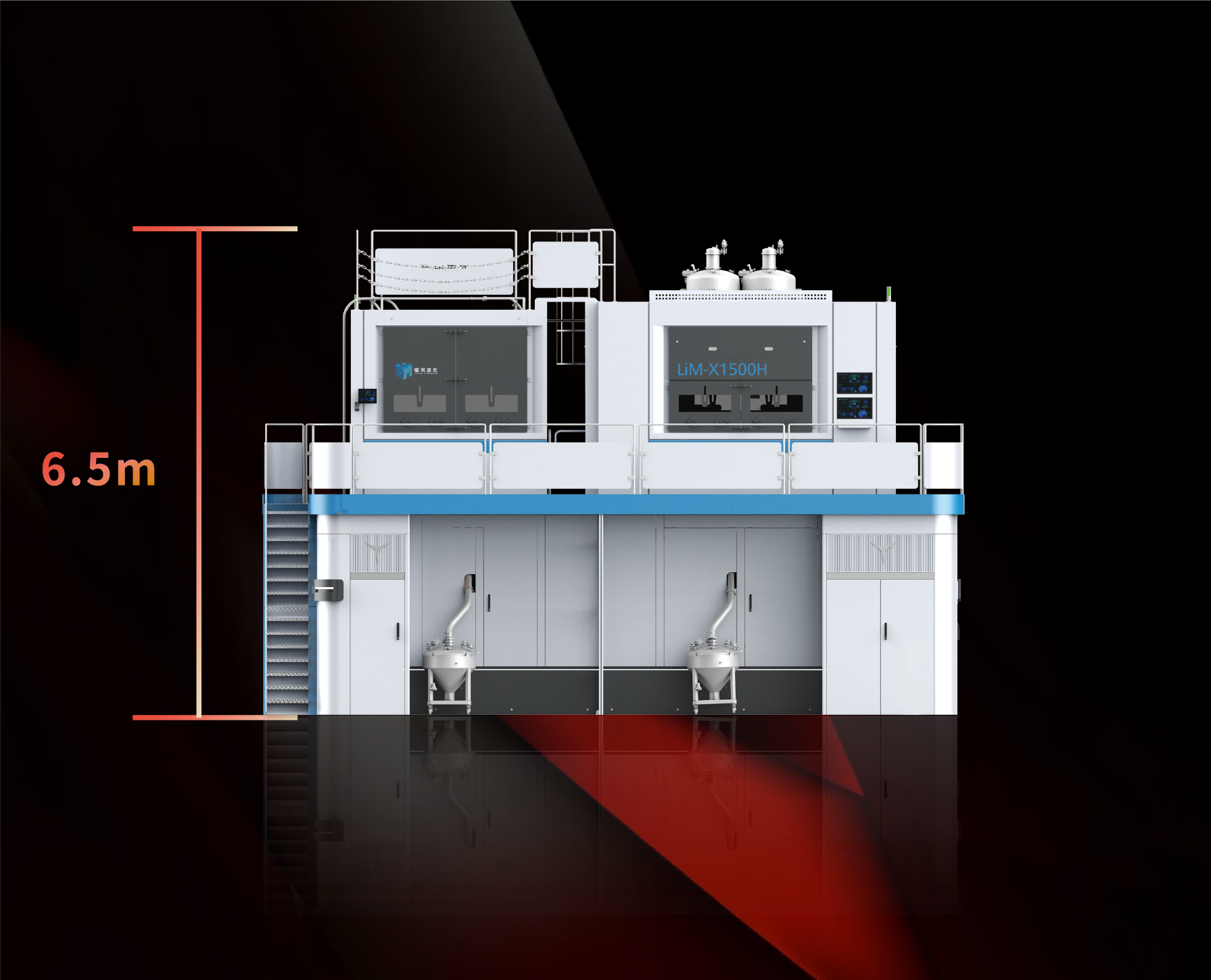

The LiM-X1500H equipment has a forming size of 1500mm×1500mm×1650mm (including a standard substrate thickness of 150mm), breaking through the forming size limitations and precisely matching the manufacturing requirements of aerospace-grade industries. It can not only achieve the integrated rapid forming of large-sized, over-specification, and complex-structured components, It can also handle the combined manufacturing or batch manufacturing tasks of medium and large-sized components.

The equipment is equipped with 16 lasers, and the maximum forming efficiency can reach 1000cm³/h. Equipped with 24 lasers, the maximum forming efficiency reaches 1500cm³/h.

Adopting an intelligent dynamic variable-speed powder spreading solution with multi-stage automatic speed change, it enables precise control in the printing area and rapid movement in the non-printing area, ensuring the quality and efficiency of powder spreading.

Single-scraper bidirectional powder spreading structure simplifies the knife adjustment procedure, making it convenient and fast. The forming chamber is equipped with one set of scraper module, which does not disrupt the inert gas environment of the forming chamber and enables online replacement of the scraper, solving the problem of scraper wear during long-term printing. The scraper drive guide rail adopts a double-layer sealed protection design, which increases its service life by more than five times.

Integrate the powder path and build a closed-loop ecosystem

Both fully automatic powder circuit circulation and split powder circuit circulation systems are available. During the printing process, the equipment can efficiently complete the powder overflow recovery, screening and supply processes, improving the powder flow efficiency and ensuring continuous and stable production.

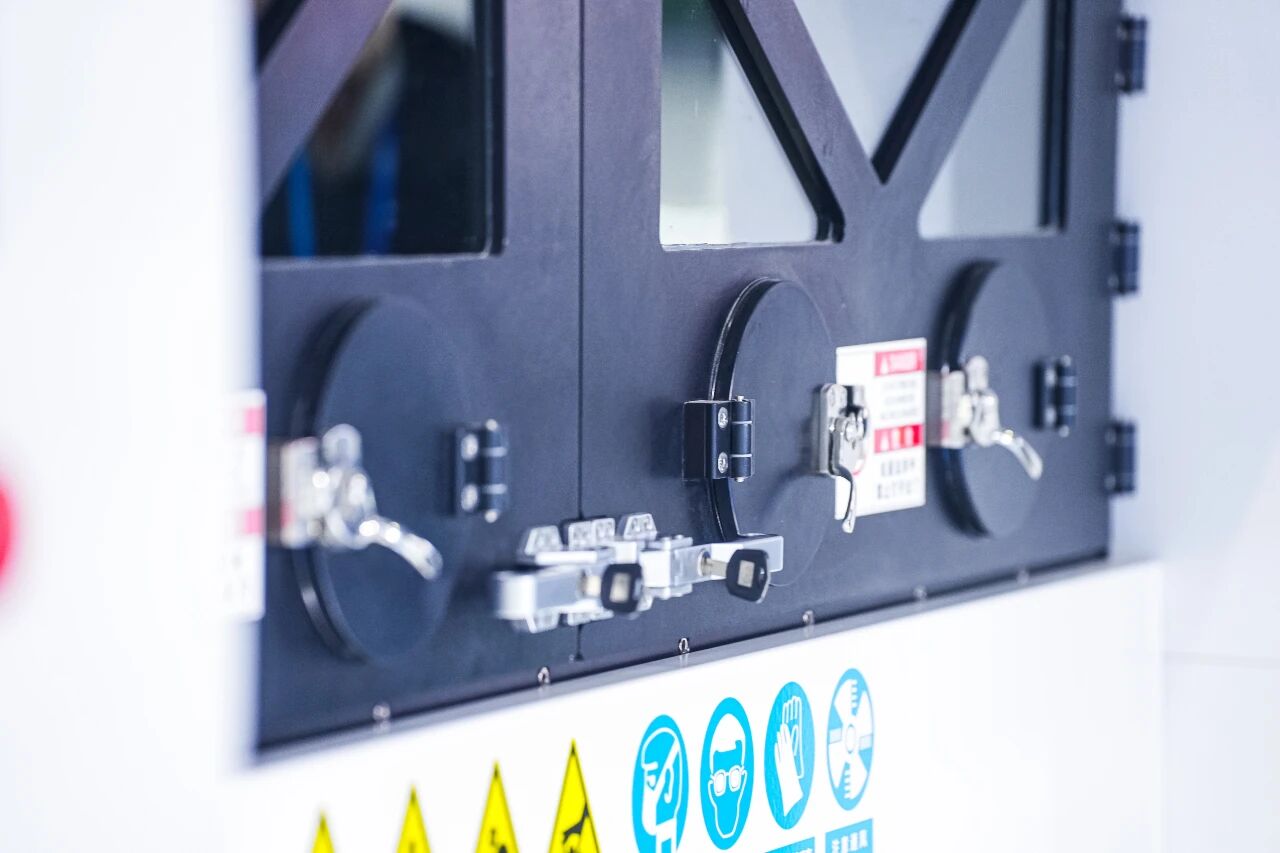

The powder cleaning and component retrieval system adopts a 4-sided 16-glove opening design. Its fully sealed structure, combined with a pressure-resistant oxygen control mechanism, ensures that operators can safely and efficiently complete powder cleaning and substrate disassembly and assembly in a low-oxygen environment.

The long-lasting filtration system ensures continuous and stable production

Equipped with a long-lasting filtration system and featuring reverse blowing function, the filtration grade is H13. It is equipped with a cyclone dust removal module, which can collect large particles in the smoke dust, reduce powder waste, lower costs, and effectively extend the service life of the filter element. The service life of the filter element exceeds 100,000 hours, and there is no need to replace the filter element throughout the entire service life cycle of the equipment, ensuring continuous printing of the equipment. The ash bucket of the filter adopts a top-lifting structure. The circulating purification system is equipped with monitoring of oxygen content, temperature and pressure to ensure safe use.

Intelligent control system, full-process self-diagnosis

The LiM-X1500H can be equipped with intelligent control systems such as powder bed monitoring modules, quantitative powder feeding systems, and oxygen content monitoring systems in the forming chamber, enabling real-time monitoring, self-diagnosis, and intelligent alarm. This ensures that the entire process from powder feeding to forming is visible, traceable, and controllable, guaranteeing the safety and controllability of the printing process and stable and consistent printing quality. Supports intelligent galvanometer calibration without manual intervention, with a single light galvanometer calibration accuracy of ≤±0.05mm. The multi-light overlap accuracy error is ≤±0.1mm, significantly improving the consistency of print quality and shortening the preparation time.

Safety certification, suitable for diverse industrial scenarios

The entire LiM-X1500H equipment has passed multiple certifications including CE safety, CE explosion-proof, FDA laser protection system safety certification and SIL Level 3 relay safety certification. Equipped with multiple monitoring interlock devices, pressure monitoring, temperature monitoring and other multiple guarantee systems, it ensures the safe and stable operation of the equipment under high-load environments.

The overall height of the machine is controlled within 6.5 meters, which is lower than that of similar equipment in size, and it has stronger adaptability to factory buildings and greater convenience in operation and maintenance.

Large-scale application has doubled the efficiency of batch production

Large-scale additive manufacturing equipment is showing a trend of batch production. While continuously expanding the forming dimensions of the equipment, it also increases the scale and quantity, establishing an automated production line with full-process coordination, which brings a brand-new solution for the batch manufacturing of super-large-sized metal components.

As a representative product of Xinjinghe in the field of ultra-meter-level equipment, the industrial application of LiM-X1500H has verified the feasibility of the related technical path. In the future, Xinjinghe will also continue to refine its technology, further seeking breakthroughs in equipment research and development, process stability, and comprehensive manufacturing costs, providing large-sized component production solutions for key fields such as aerospace and energy power, and promoting the iteration and upgrading of high-end manufacturing with concrete actions.